Background

Mallard Creek Polymers partnered with NOVONIX to study and compare the performance of their Styrene-Butadiene Rubber (SBR) to a commercial SBR used as an anode binder in Li-ion cell prototyping.

Two of Mallard Creek Polymers’ SBR materials were evaluated as a ‘drop-in’ replacement for the commercial SBR material used in NOVONIX’s cell prototyping line. This allowed material performance to be evaluated from slurry mixing through to cell performance.

Cell Building

The project began with slurry mixing, followed by electrode coating and calendaring. NMC-graphite 18650 cells were built and tested for this project.

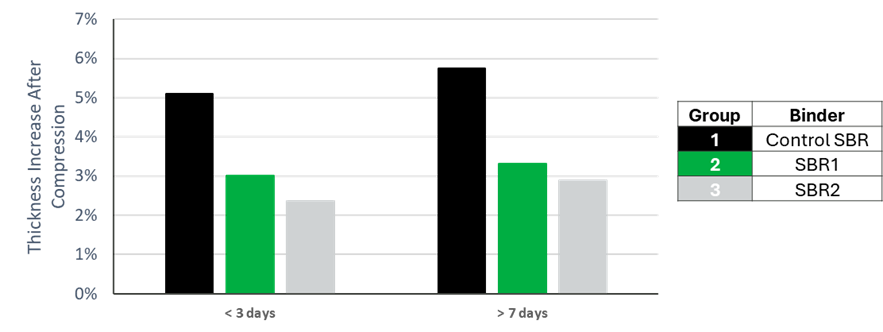

Mallard Creek Polymers’ SBR materials produce a small amount of foam after three hours of high shear mixing. After an additional short vacuum step was added, the foam was removed and resolved this issue. During electrode coating, Mallard Creek Polymer’s materials performed similarly to the reference, yielding consistent coatings with no processing issues. During the calendaring process, the Mallard Creek Polymers SRB electrodes had less rebound compared to the commercial reference material.

Electrode ‘rebound’ refers to the electrode thickness increase, post-compression, due to the elastic properties of the coated electrode. Generally, a lower rebound is desired to target a compressed coating density. Both Mallard Creek Polymers’ SBRs outperformed the commercial SBR.

Compressed electrodes demonstrated good adhesion to the substrates during the adhesion testing. Electrode slitting, cell building, and cell filling showed no significant differences compared to the commercial SBR group.

Cell Testing

NOVONIX provides various types of performance testing to obtain clear results for prospective cell materials, designs, and use cases.

The following tests were executed:

- Formation testing

- C10-C10 Ultra High Precision Coulometry (UHPC) cycling (40°C)

- 1C-1C cycle aging cycling (25°C)

- C3-C3 cycling aging (40°C)

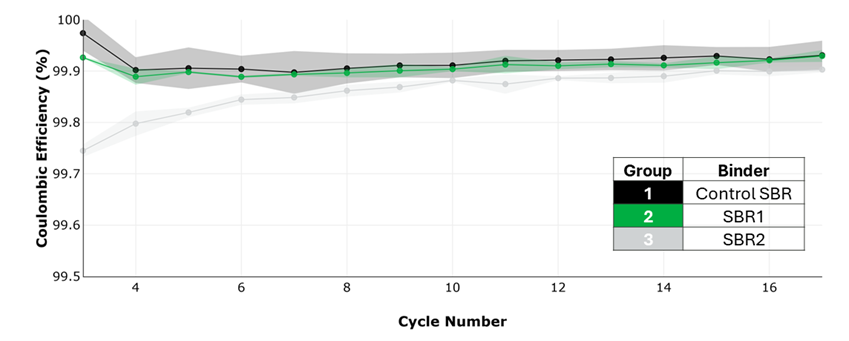

In formation testing, Coulombic Efficiency (CE) and the first Discharge Capacity were nearly identical for all groups, and matched the cell design values.

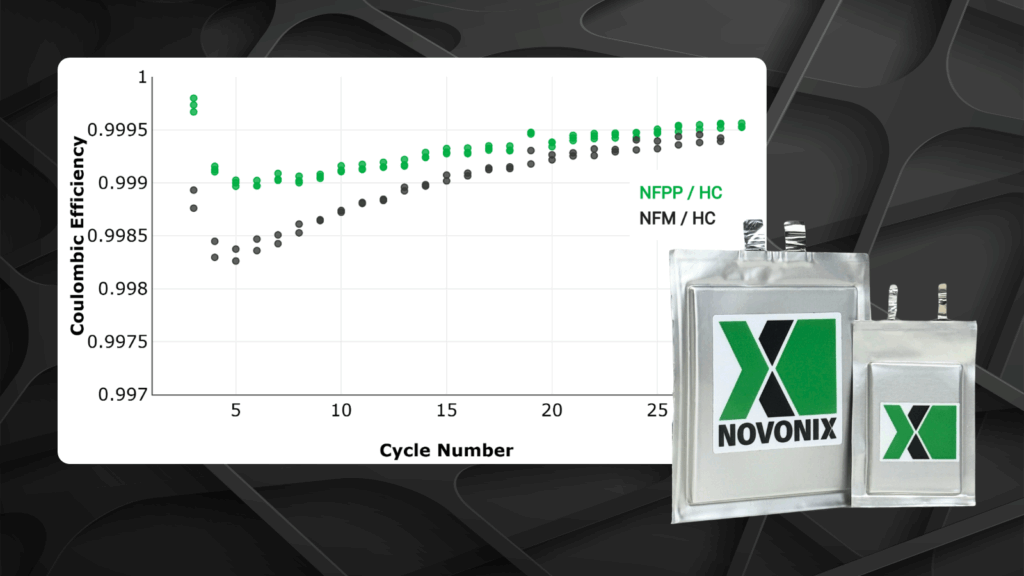

NOVONIX Ultra-High Precision Coulometry (UHPC) equipment was used to measure CE. NOVONIX UHPC can be used to very accurately and precisely measure differences in electrochemical performance in a short timeframe. Testing was completed at a low rate of C/10 to evaluate differences in electrochemical stability by removing the effects of kinetics on cycle performance. At the end of UHPC cycling, after only 2 weeks of testing, the CE was nearly identical between all groups, indicating no significant differences in electrochemical stability were caused by any of the SBR materials. These results agreed with longer term cycle aging tests.

Conclusion

Mallard Creek Polymers’ SBR1 and SBR2 tested at NOVONIX worked well as a drop-in solution to NOVONIX’s cell prototyping line. Electrode rebound testing revealed lower rebound for SBR1 and SBR2 compared to the commercial SBR, and electrode adhesion was excellent for SBR2 compared to the commercial SBR. Cell testing demonstrated similar performance for all groups.

Overall, Mallard Creek Polymers’ SBR1 and SBR2 demonstrated good performance as an anode binder for Li-ion cells.

To download the full report from Mallard Creek Polymers, complete the form below.

"*" indicates required fields

Our R&D Services Pilot Line

NOVONIX partners with companies all over the world to be a trusted research and development partner, by leveraging its pilot line, cell testing lab, and team of knowledgeable technicians, engineers and scientists. Whether you are a materials manufacturer, chemical company, technology integrator, cell manufacturer, tier-1 OEM or a startup, NOVONIX has the equipment and the team to help you accelerate your R&D.

- We offer expertise from materials evaluation through full-cell design and performance analysis.

- Setup for small-to-medium scale (10-500) cell prototyping up .

- Testing capabilities with over 3000 channels, including NOVONIX UHPC.

If you are looking for a partner to help with your material evaluation, cell prototyping, or testing validation, reach out today!