Since 2014, the Harvard University Aziz group has been dedicated to studying and developing Aqueous Organic Redox Flow Batteries due to their scalability and cost-effectiveness, making them a promising solution for large-scale electrochemical energy storage. However, the current limitations of Redox-Active Organic Molecules (RAOMs) include degradation over time, which impacts both the economic feasibility and performance of these batteries. Despite these challenges, the team has made significant strides in understanding how these molecules decompose and, more impressively, how to mitigate and even reverse this decomposition. Their innovative approach earned one molecule the nickname “zombie quinone” in the lab due to its death-defying rejuvenation ability. The team has reduced the battery’s capacity fade rate by at least a factor of 40, allowing the battery to be composed entirely of low-cost chemicals.

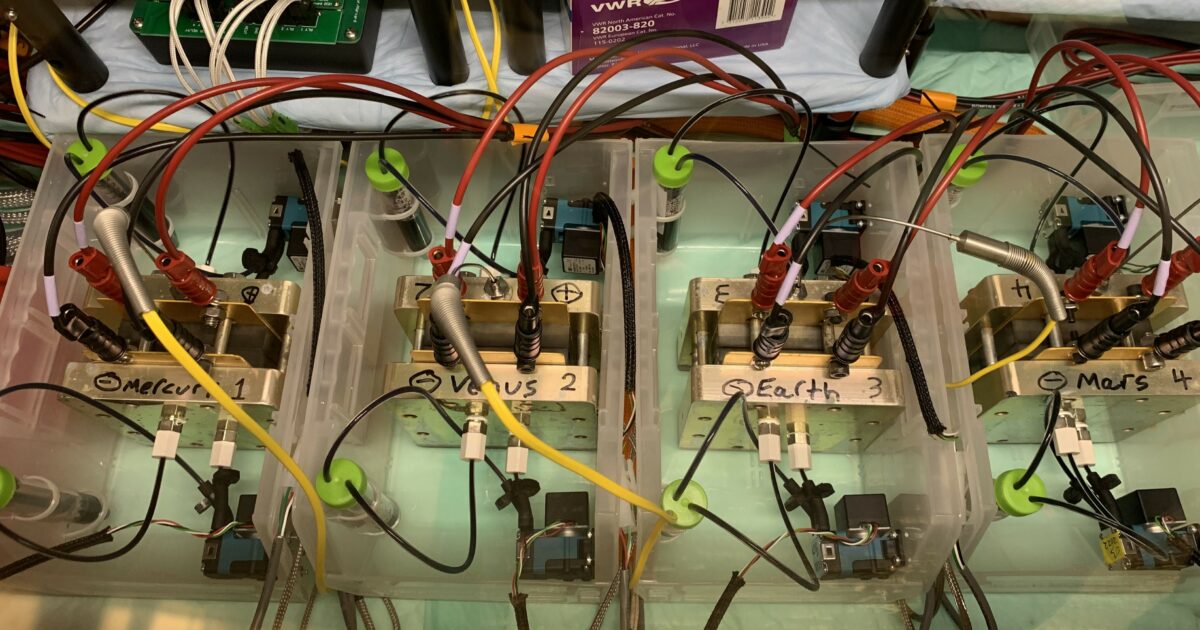

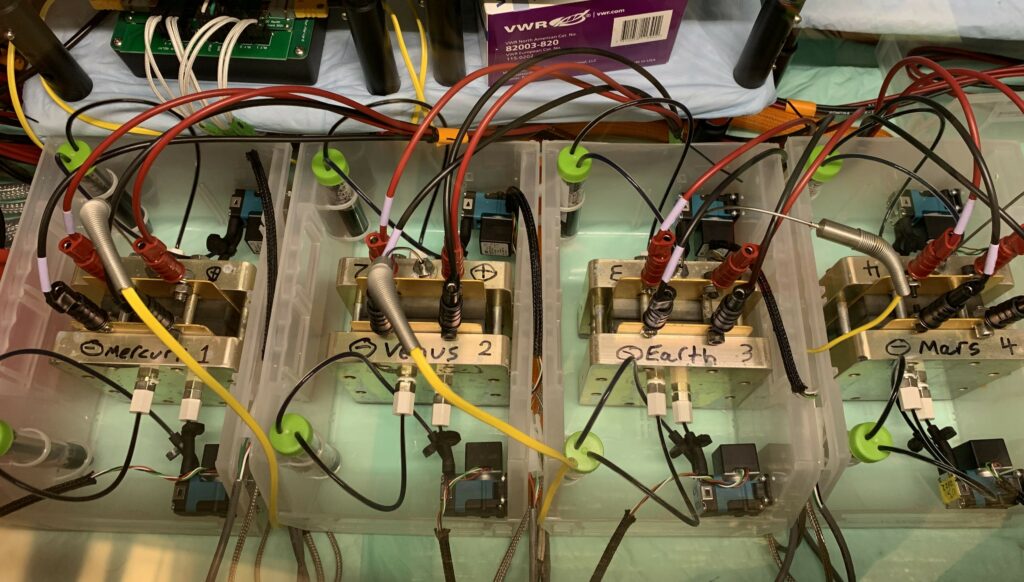

Recently, the team, led by Michael Aziz and Eric Fell, has tested various common organic compounds (anthraquinones) used in flow batteries, measuring how their capacity fades over time. They compared the performance of cells with identical designs but different cycling methods, testing three common approaches: constant current, constant current constant voltage, and constant voltage. To achieve precise testing results and understand the degradation mechanisms, they developed a high-throughput system capable of efficiently testing aqueous organic redox flow battery active material. This setup allows them to cycle through many cells quickly to evaluate their performance. They utilize NOVONIX Ultra-High Precision Coulometry (UHPC) channel modules, equipped with a DC-offset unit with a voltage range of -1 to +4V for all cell cycling. The temperature-controlled cells are cycled in a glove box, also used for electrolyte preparation. Maintaining temperature control and accurate capacity measurements is crucial for reliable performance evaluation.

By analyzing the results of this study, the Harvard team has identified key factors to consider when cycling these batteries, providing valuable insights into how different cycling protocols affect the longevity and performance of RAOMs in flow batteries. Their work emphasizes the importance of standardizing measurement conditions, reducing variability, and incorporating temperature control to achieve meaningful assessments of aqueous organic redox flow battery lifetimes.

In the following Q&A, Eric Fell, who led this recent study, shares his insights and experiences in advancing the research and testing of these innovative battery technologies with the NOVONIX UHPC Channel Module.

Q1: Can you provide a brief overview of why Harvard decided to research Redox Flow Battery technology?

An opportune collaboration that started over a decade ago between our group and the groups of Roy Gordon and Alán Aspuru-Guzik in Harvard’s Department of Chemistry and Chemical Biology set out to explore a family of RAOMs, known as quinones, with favorable (electro) chemical properties for use as energy storage materials. At the same time, the cost of electricity generated from renewables (ex. solar, wind) was falling but their intermittency required the ability to store large amounts of electrical energy. Redox Flow Batteries can independently scale the energy and power components of the system by keeping all the redox-active species in liquid form and—unlike solid-electrode batteries—can maintain discharge at peak power for longer durations. Thus, the vision was born of a metal-free, aqueous organic redox flow battery with a research direction of discovering new RAOMs made of earth-abundant atoms to enable massive electrical energy storage at a significantly reduced cost.

Q2: What challenges were you facing with your previous testing methods and equipment?

Small inconveniences in other battery cycling equipment that compounded over time were preventing us from fully embracing high-throughput testing. This included lower-precision coulometry, proprietary file types that hindered automated data conversion and analysis, inability to create diverse cycling protocols, and the lack of capabilities to perform batch experiments.

Q3: How did you first learn about NOVONIX UHPC systems, and what made you decide to implement it in your testing processes?

Early discussions between our group and Jeff Dahn in 2016 led to the conclusion that we would be in the best position to enable high-precision, high-throughput electrochemical characterization of RAOMs in flow cells by employing a NOVONIX UHPC system. Especially important to us was the ability to apply negative voltages via DC-offset units for symmetric cell cycling, and high-precision coulometry to distinguish between RAOM lifetimes of years vs. decades or longer.

Q4: How has NOVONIX UHPC systems improved the accuracy and reliability of your flow testing?

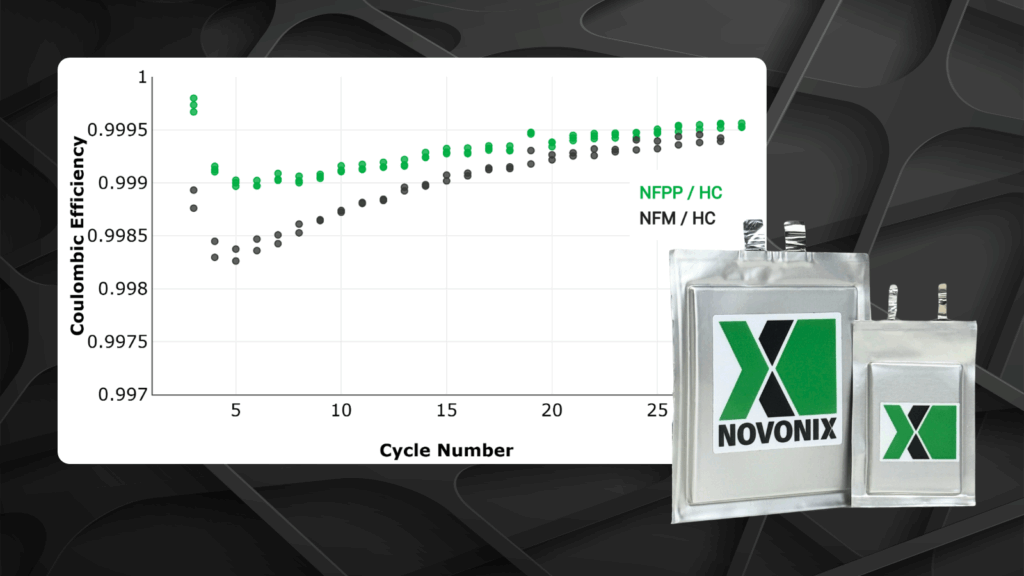

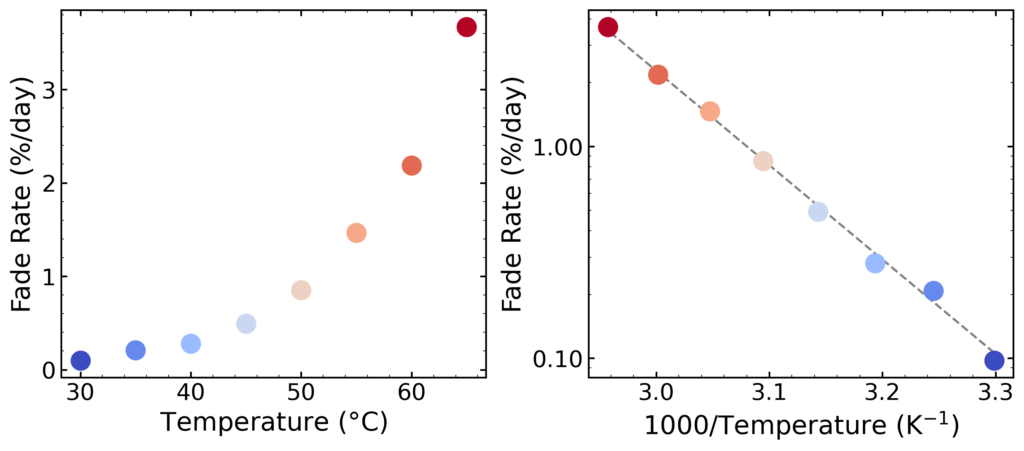

The aqueous RAOMs we test undergo (electro)chemical degradation in solution, thus we predominantly focus on temporal capacity fade rates resulting from chemical decay kinetics. This means that regression analysis of noisy coulometry data cannot be improved by cycling at higher rates as we care about capacity fade per time, not cycle. The accuracy afforded by the UHPC channels allows us to minimize the amount of cycling time required to adequately assess temporal capacity fade rates and screen extremely stable RAOMs.

Q5: Can you share a specific example or scenario where NOVONIX UHPC features made a significant impact on your testing outcomes?

Having previously used many different battery cyclers, I can say that there are quite a few features that NOVONIX has streamlined for a more efficient battery-cycling-user experience. One feature that is often overlooked when comparing cyclers is the way in which a cycler returns raw data i.e., the file system, file format, file type, etc. NOVONIX’s use of non-proprietary file types and structured cycling (meta)data, means that raw data is automatically machine readable by our in-house Python scripts for parsing, cleaning, and storing cell data. This enables a pipeline of high-throughput battery data analytics that is required to complement our high-throughput testing capabilities. Consequently, significant people-hours have been saved and our lab’s research throughput has dramatically increased.

Q6: Have there been any unexpected benefits or insights gained from using a NOVONIX UHPC system that you didn’t anticipate?

Using a NOVONIX UHPC system, we were able to see a significant noise reduction in coulometry data. This allowed us to determine that subtle diurnal fluctuations in lab temperature—even in the controlled glovebox environment—were affecting cycling-protocol-dependent accessible capacity in our batteries. This finding motivated the use of temperature-controlled cells in future generations of our high-throughput system to accurately benchmark temporal capacity fade rates.

One unexpected benefit has been the flexibility to install NOVONIX UHPC channel modules in opposite orientations within racks to accommodate the unique extended multi-glovebox layout within our high-throughput testing facility.

Q7: How has the integration of a NOVONIX UHPC system affected your overall development timeline or product performance?

We saw a sixfold increase in the lab’s throughput capabilities for evaluating battery performance. The ability to implement high-throughput testing permitted not only rigorous benchmarking of candidate RAOMs, but also the development of temperature-accelerated lifetime evaluation for redox flow batteries and the first capability in the aqueous organic flow battery community of predicting battery performance under real-world use cases. Furthermore, NOVONIX UHPC was instrumental in the successful vetting of our lab’s technology that led to a spinout company.

Q8: What feedback have you received from your team or stakeholders regarding the use of NOVONIX UHPC?

Having standalone software capabilities for quick data visualization (UHPC Plot) has allowed team members to assess battery data and design future experiments from anywhere. Overall, NOVONIX UHPC has been a force multiplier for our group and has provided new dimensions in the flow battery characterization parameter space to explore. The screening process of candidate molecules for long lifetime flow batteries has been significantly expedited, and research directions are now tackled more rapidly.

Further Applications of UHPC

UHPC has emerged as a cornerstone technology in battery research and development since its invention in 2013. Originally designed to address the limitations of traditional battery cyclers in delivering quick and reliable results, UHPC has since expanded across a broad spectrum of battery technologies and has been instrumental in advancing sodium-ion and solid-state batteries, in addition to its primary application with lithium-ion batteries.

NOVONIX provides the only UHPC systems available today and those systems span multiple sectors, including electric vehicles, grid energy storage, consumer electronics, and industrial equipment. NOVONIX channel modules provide high-resolution, low-noise data that sets it apart from other battery cyclers, offering metrics such as charge endpoint capacity slippage and accurate Coulombic Efficiency after limited cycling. The company’s advanced UHPC software suite also gives users the tools to create and manage detailed test protocols with real-time monitoring of each channel’s performance, NOVONIX UHPC systems are valuable tools in reducing R&D timelines, allowing researchers and developers to focus on improving materials and processes with confidence in their data.

With industry leading precision and accuracy, continuous software features updates, thermal chambers, and the addition of higher amperage modules (10 Amp and 20 Amp), NOVONIX UHPC continues to drive the evolution of modern battery technologies.