NOVONIX Limited (ASX:NVX) (NOVONIX) and Lithium Energy Limited (ASX:LEL) (Lithium Energy) are pleased to provide the following update on the spin-out and Initial Public Offering (IPO) and ASX listing of Axon Graphite Limited[1] (proposed ASX Code : AXG) (Axon Graphite), which encompasses the merger of the high-grade natural graphite assets of Lithium Energy (the Burke and Corella Deposits) and NOVONIX (the Mt Dromedary Deposit) to form a distinct vertically integrated Battery Anode Material (BAM) business in Queensland, Australia.[2]

As part of the IPO process, Axon Graphite has undertaken a review of NOVONIX’s Mt Dromedary Deposit (previously assessed in 2016[3]) and provides the following updated Mineral Resource Estimate (MRE) for Mt Dromedary:

- Total Mineral Resource of 7Mt at 14.5% Total Graphitic Carbon (TGC) for a total of 1.83Mt contained graphite (at a 5% TGC cut-off grade), comprising:

- Indicated Mineral Resource of 8.3Mt at 15.2% for 1,260kt of contained graphite; and

- Inferred Mineral Resource of 4.3Mt at 13.2% TGC for 570kt of contained graphite; and

- Within the mineralisation envelope, there is included a higher grade Total Mineral Resource of 5Mt at 18.4% TGC for 1.56Mt of contained graphite (at a 10% TGC cut-off grade).

The adoption of a 5% TGC cut-off grade for the updated Mt Dromedary MRE (previously reported at 4% TGC3) is now consistent with the 5% TGC cut-off grade adopted for the Burke and Corella Deposit MRE’s. The companies also note that the Competent Person who assessed the updated Mt Dromedary MRE also assessed the Burke and Corella MRE’s in 2023. The review of the Mt Dromedary MRE will also assist Axon Graphite in its post-IPO/listing resource development work (as outlined below).

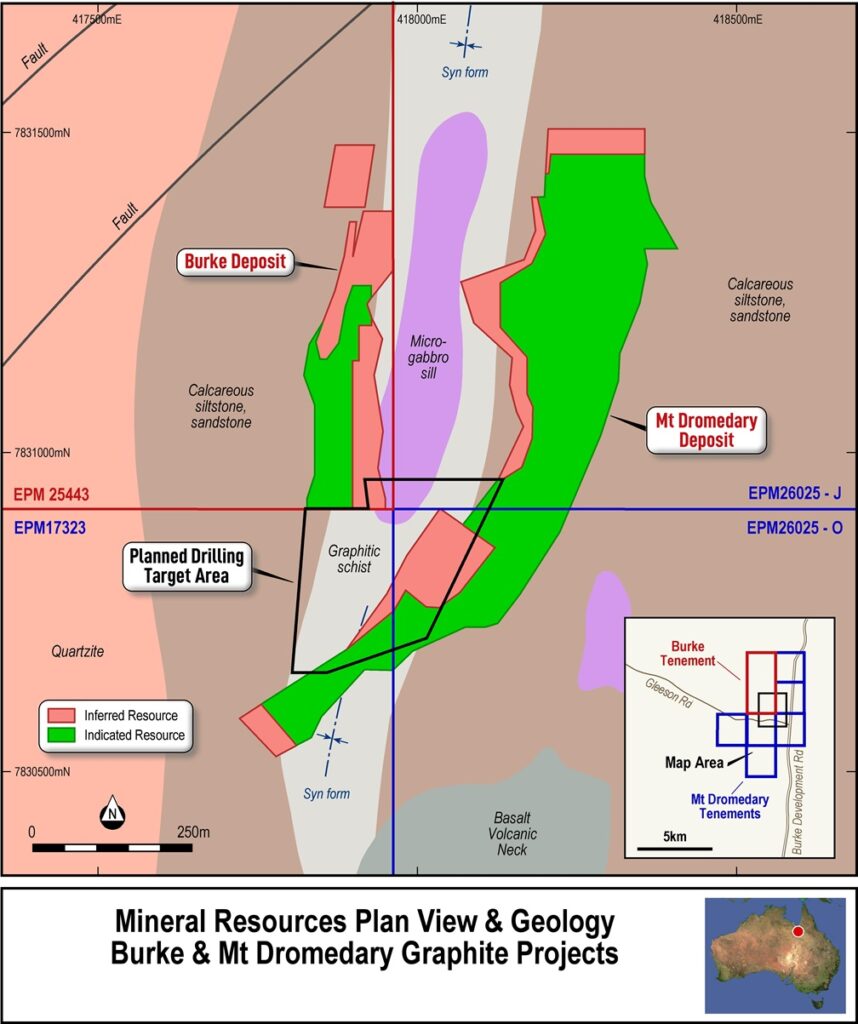

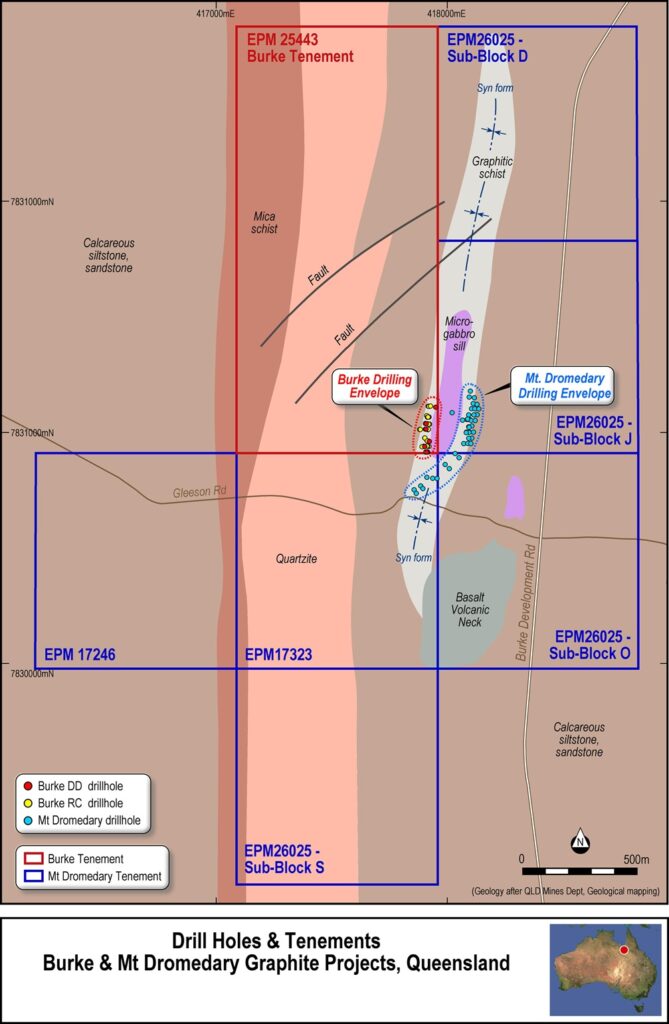

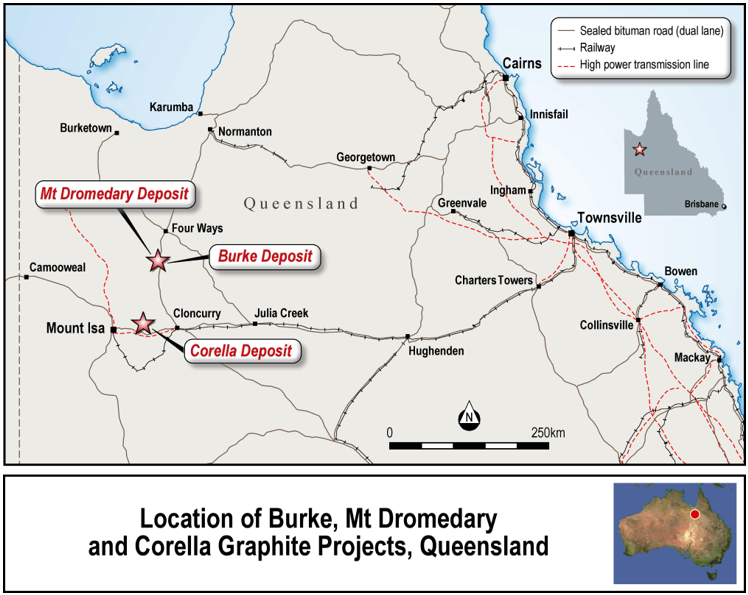

The Mt Dromedary tenements are directly adjoining the Burke tenement (refer Figures 1 and 2) and the Burke Deposit is a continuation of the graphite mineralisation within the Mt Dromedary Deposit. The combination of these two adjoining high-grade graphite deposits creates the potential for significant operational synergies and economies of scale through a potentially larger scale open-pit mining operation to provide feedstock for a vertically integrated BAM Facility based in Queensland.

Figure 1: Burke and Mt Dromedary Graphite Projects: Tenements, Geology, Drill Holes and Drilling Envelopes

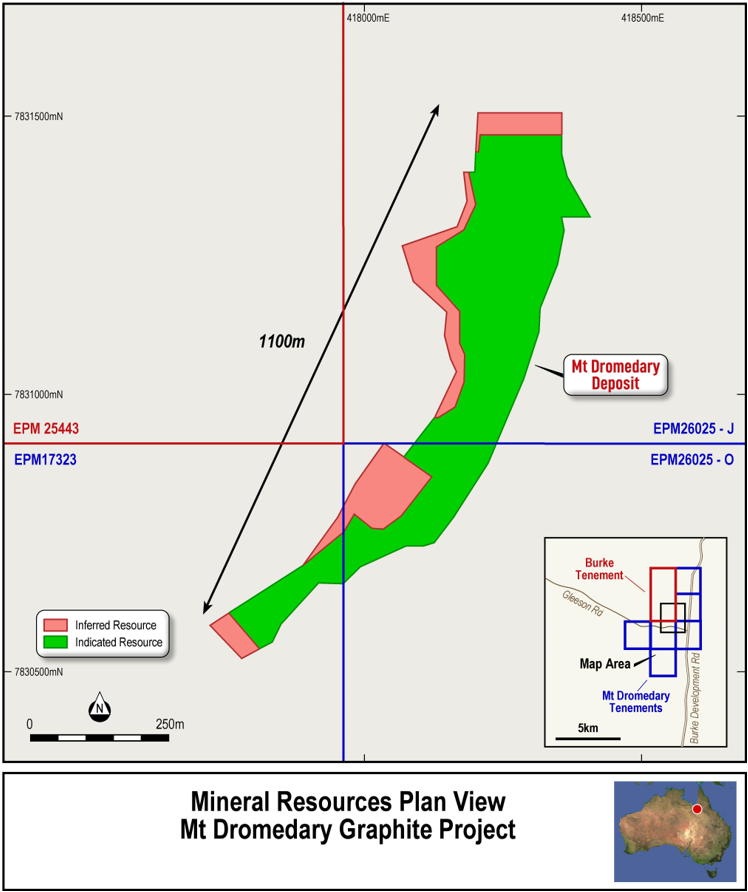

In addition, graphite mineralisation is open to the north and south and in between the currently defined Mt Dromedary and Burke Deposits (refer Figures 1 and 2). Upon the successful completion of Axon Graphite’s IPO and admission to ASX (Listing), Axon Graphite proposes to:

- review existing drilling data and resource models for the Burke and Mt Dromedary Deposits to delineate a combined MRE for the Burke/Mt Dromedary Deposits; and

- undertake resource development drilling (comprising reverse circulation (RC) and diamond core (metallurgical and geotechnical) holes) on the Burke and Mt Dromedary tenements to increase and upgrade the (abovementioned) combined Mineral Resource (refer Figure 2 for the planned drilling target area).

Figure 2: Burke and Mt Dromedary Deposits – Indicated and Inferred Mineral Resources Plan View,

Geology and Planned Drilling Target Area

Post-Listing, Axon Graphite will hold an interest in three high grade graphite deposits in Queensland with access to key infrastructure, including ports and transport links facilitating potential future export to major international markets (refer Figure 5). These graphite deposits have a combined contained graphite inventory of 4.42Mt comprising:

- the Mt Dromedary Deposit (currently held by NOVONIX) – having a total JORC Indicated and Inferred Mineral Resource of 7Mt graphite at 14.5% TGC, for a total 1.83Mt of contained graphite;

- the Burke Deposit (currently held by Lithium Energy) – having a total JORC Indicated and Inferred Mineral Resource of 1Mt graphite at 14.4% TGC, for 1.31Mt of contained graphite[4]; and

- the Corella Deposit (currently held by Lithium Energy) – having a total JORC Inferred Mineral Resource of 5Mt graphite at 9.5% TGC, for 1.28Mt of contained graphite[5].

The Burke and Mt Dromedary Deposits comprise resources of graphite with average (>14% TGC) grades significantly higher than most global peers.

Furthermore:

- Axon Graphite will seek to capitalise on expected growth in electric vehicle (EV) sales and battery-based grid scale energy storage systems over the coming decades, through the production and sale of graphite-based BAM, one of the key components of EV and grid storage batteries.

- Axon Graphite intends to merge the Burke and Mt Dromedary Projects into one combined project and construct and operate a BAM Pilot Plant to undertake further testwork and optimisation to facilitate the design and development of a vertically integrated BAM Manufacturing Facility (BAM Facility) located in Queensland.

- The BAM Facility is proposed to manufacture spherical purified graphite (SPG)/coated SPG (CSPG) utilising graphite mined and concentrated (into flake graphite) from the combined Burke and Mt Dromedary Deposits as feedstock.

- These SPG/CSPG products will be sold as a BAM for use in the manufacturing of LIB or battery energy storage solutions

The Prospectus for the ($15 Million to $25 Million) IPO of Axon Graphite is currently being finalised in preparation for lodgement with ASIC. NOVONIX and Lithium Energy will provide further updates to the ASX on the indicative timetable for the Axon Graphite IPO, including in relation to the record dates for determining entitlements under the Priority Offers to eligible NOVONIX and Lithium Energy shareholders.

Updated Mt Dromedary Mineral Resource Estimate

Table 1 – Mt Dromedary September 2024 Mineral Resource Estimate (5% TGC Cut-off Grade)

| Category | Weathering State | Resource (Mt) | TGC (%) | Contained Graphite (kt) |

| Indicated Mineral Resource | Weathered | 1.5 | 14.8 | 230 |

| Primary | 6.8 | 15.2 | 1,030 | |

| Sub-total | 8.3 | 15.2 | 1,260 | |

| Inferred Mineral Resource | Weathered | 0.3 | 11.8 | 30 |

| Primary | 4.1 | 13.3 | 540 | |

| Sub-total | 4.3 | 13.2 | 570 | |

| Total Indicated and Inferred Mineral Resource | Weathered | 1.8 | 14.3 | 260 |

| Primary | 10.8 | 14.5 | 1,570 | |

| TOTAL | 12.7 | 14.5 | 1,830 |

Notes:

-

- TGC = total graphitic carbon; Mineral Resource estimates are reported above a cut-off grade of 5% TGC; Mineral Resources reported on a dry in-situ basis; Totals may differ due to rounding.

- All Mineral Resources figures reported in Table 1 above represent estimates at September, 2024. Mineral Resource estimates are not precise calculations, being dependent on the interpretation of limited information on the location, shape and continuity of the occurrence and on the available sampling results.

- Mineral Resources are reported in accordance with the Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (The Joint Ore Reserves Committee Code – JORC 2012 Edition).

- The Statement of Estimates of Mineral Resources has been compiled by Mr. Shaun Searle who is a Director of Ashmore Advisory Pty Ltd and a Member of the Australasian Institute of Geoscientists (AIG). Searle has sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration and to the activity that he has undertaken to qualify as a Competent Person as defined in the JORC Code (2012).

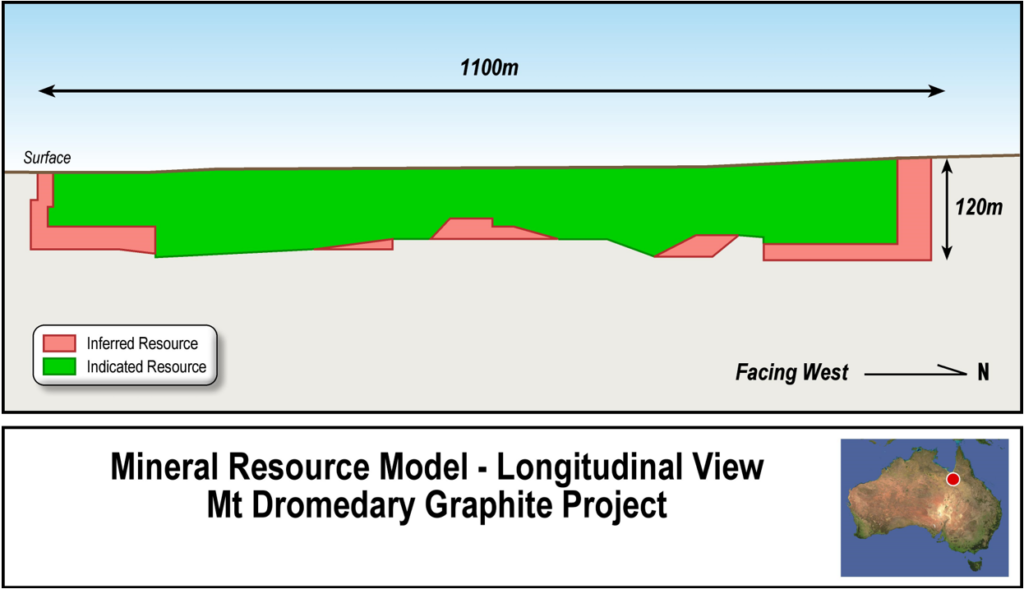

Figure 3: Mt Dromedary Deposit – Indicated and Inferred Mineral Resources Longitudinal View

Figure 4: Mt Dromedary Deposit – Indicated and Inferred Mineral Resources Plan View

In addition to the high-grade nature of the Mt Dromedary Deposit[6]:

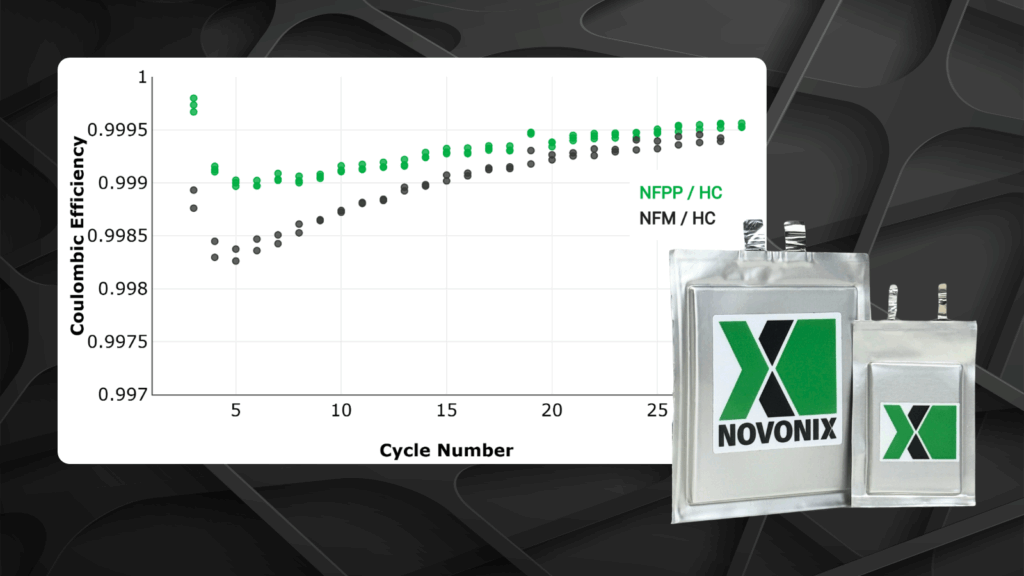

- metallurgical testing has been completed to determine the suitability of the Mt Dromedary graphite for producing an export grade concentrate;

- given the most attractive growth and premium pricing opportunity in the graphite market relates to the use of graphite in lithium-ion batteries (LIB), further independent expert laboratory testing (including thermal purification, battery test cell construction and electrochemical) in the US has confirmed that graphite concentrate produced from the Mt Dromedary Deposit is suitable for LIB applications;

- physical examination of the Mt Dromedary graphite concentrate powders and electrochemical test work results on the LIB cells showed that the materials have high purity and good electrochemistry with high reversible capacity in battery-application testing;

- the Mt Dromedary Deposit is adjacent to a sealed highway connecting to multiple export ports with bulk and containerised export options and has access to well-developed back-haul and container transport capacity and logistics (by road and ocean); and

- the Mt Dromedary Deposit is potentially amenable to low cost open-pit mining.

Mt Dromedary Graphite Project Location and Tenements

The Mt Dromedary Graphite Project comprises the Mt Dromedary tenements (of ~19.41km2), which are contiguous to the Burke tenement (EPM 25443 of ~6.47km2), located ~130km by road north of Cloncurry, adjacent to the Burke Development Road (refer Figures 1 and 5). Lithium Energy’s Corella Graphite Project (EPM 25696 of ~19.41km2) is located ~40km by road west of Cloncurry and ~170km by road south of the Burke/Mt Dromedary tenements, adjacent to the Barkly Highway that links Mount Isa to Cloncurry (refer Figure 5).

Table 2 – Mt Dromedary Project Tenements

| Tenement Holder |

Tenement Name |

Tenement No. |

Grant Date |

Expiry Date |

Area (sub-blocks) |

Area (km²) |

| MD South Tenements Pty Ltd |

Pigeon South | EPM 17246 | 26/10/2010 | 25/10/2027 | 1 | ~3.235 |

| Pigeon South | EPM 17323 | 20/10/2010 | 19/10/2027 | 1 | ~3.235 | |

| Exco Resources Pty Limited |

Boomarra Consolidation |

EPM 26025 (Sub-Blocks D, J, O and S within Normanton 3123 Block) |

14/12/2015 | 13/12/2025 | 4 | ~12.94 |

Notes:

-

- EPM means Exploration Permit for Minerals.

- MD South Tenements Pty Ltd (MDSTPL) is a wholly-owned subsidiary of NOVONIX.

- Interest in EPM 26025 is held pursuant to:

- Mount Dromedary Development Rights Agreement between NOVONIX and Exco Resources Pty Limited ACN 080 339 671 (formerly Exco Resources Limited) (Exco) dated 29 August 2016 (DRA)– refer also, NVX ASX Announcement dated 29 August 2016: Washington H. Soul Pattinson and Company to Merge JV Interest into GraphiteCorp; the DRA was assigned by NOVONIX to MDSTPL under the MRD; and

- Mineral Rights Deed (Mt Dromedary MDL) between NOVONIX, MDSTPL and Exco 23 February 2024 (MRD).

The tenements have access to well-developed transport infrastructure, including airports at Cloncurry and Mount Isa (located ~250km by road from Burke and Mt Dromedary) and a Port in Townsville (located ~783km by road or rail from Cloncurry) (refer Figure 5).

Figure 5: Location of NOVONIX’s Mt Dromedary Graphite Project and

Lithium Energy’s Burke and Corella Graphite Projects in Queensland, Australia

Geology and Geological Interpretation

The Mt Dromedary Graphite Project is hosted by a mapped graphitic schist as a sub unit of the Corella Formation, within the Mary Kathleen Group and is of Proterozoic age. The graphitic schists within the deposit area are intruded by the Black Mountain (1,685-1,640Ma) gabbro, and sills, with subsequent metamorphism to amphibolite grade during the Isan Orogeny 1,600-1,580Ma. The style of mineralisation is crystalline graphite within graphitic schists.

Sampling and Sub-Sampling Techniques

For diamond core drilling, HQ triple tube diamond core was selected as the optimum sampling method for drilling the graphite mineralised zones at the Mt Dromedary deposit, on the basis of maximising recovery of graphite, as the method minimises disturbance to core, limiting potential losses in drilling water. Drill core was oriented with a Reflex Act II orientation tool. Diamond core holes were sampled at 1m intervals or to geological contacts. Core was cut in half with a core saw.

RC drilling was the predominant drill method at Mt Dromedary. A face sampling hammer was used with sampling conducted on 1m intervals. For the Phase One RC drilling program (2015)[7], the 1m samples were split with a 50/50 riffle splitter and composited to 2m. For the Phase 2 (2015)[8] and Phase 3 (2016)[9] RC drilling programs, the 1m samples were split with a 75/25 rig mounted splitter and composited to 2m.

Samples were submitted to ALS Minerals Laboratory in Mount Isa, Queensland, for sample preparation. Samples were weighed, assigned a unique bar code and logged into the ALS system. The entire sample was oven dried at 105˚ and crushed to -2mm. A 300g sub-sample of the crushed material was then pulverised to better than 85% passing -75µm using a LM5 pulveriser. The pulverised sample was split with multiple feed in a Jones riffle splitter until a 100-200g sub-sample was obtained.

Drilling Techniques

Diamond core drilling was undertaken and HQTT core recovered in 3m core barrels. Core orientation was routinely undertaken during drilling using a Reflex ACT II tool. Geotechnical data (foliation, bedding, fault, joint and fracture orientations) was collected continuously and automatically by the High Resolution Acoustic Televiewer downhole instrument supplied by Geology Pty Ltd of Hervey Bay, Queensland.

The RC hammer bit had a measured diameter of 123mm. A larger diameter RC hammer was used to drill an initial pre-collar of 4m in the soil-colluvium profile, which was then cased-off using PVC pipe to avoid unconsolidated material falling behind the drill rods.

Classification Criteria

The Mt Dromedary Mineral Resource was classified as Indicated and Inferred Mineral Resource based on data quality, sample spacing, and lode continuity. The Indicated Mineral Resource was defined within areas of close spaced RC and diamond core drilling of predominantly 50m by 30m, and where the continuity and predictability of the lode positions was good, with some Indicated Mineral Resource classified where good grade continuity occurred up to 100m by 50m. The Inferred Mineral Resource was assigned to areas where drill hole spacing was greater than 100m by 50m, where small, isolated pods of mineralisation occur outside the main mineralised zones, and to geologically complex zones.

Sample Analysis Method

One-metre intervals of quarter-split drill core and RC drill chips were submitted into Intertek sample preparation laboratory in Townsville, Queensland. Samples were analysed at ALS Minerals Laboratory in Brisbane, Queensland. Analysis of the samples was conducted using the following methods: Method C-IR18 Total Graphitic Carbon, Method C-IR07 Total Carbon, Method S-IR08 Total Sulphur, Method Ash-01 Ash Content, Method ME-GRA05g Loss on Ignition, Method ME-ICP06 Major Oxides, Method ME-MS81 Ultra Trace Level Method, and Method ME-ACD81 Four Acid Digest. The methods are appropriate for understanding graphite deposits and are total methods.

Estimation Methodology

The mineralisation was constrained by wireframes prepared using a nominal 1% TGC cut-off grade, plus geological logging. Following a review of the population histograms and log probability plots and noting the low coefficient of variation statistics, it was determined that the application of high grade cuts was not warranted.

The block model parent block dimensions used were 25m NS by 12.5m EW by 5m vertical with sub-cells of 6.25m by 3.125m by 1.25m. The parent block size dimension was selected on the results obtained from KNA that suggested this was the optimal block size for the dataset. The Mineral Resource block model was created and estimated in Surpac using Ordinary Kriging (“OK”) grade interpolation. An orientated ‘ellipsoid’ search was used to select data and adjusted to account for the variations in lode orientations, however all other parameters were taken from the variography.

Up to three passes were used for each domain. First pass had a range of 80m, with a minimum of 4 samples. For the second pass, the range was extended to 150m, with a minimum of 4 samples. For the third pass, the range was extended to 300m, with a minimum of 2 samples. A maximum of 12 samples was used for all passes, with a maximum of 4 samples per hole.

A total of 795 bulk density measurements were taken on core samples collected from diamond holes drilled at the Mt Dromedary deposit using the dry weight / wet weight technique. Bulk densities were assigned averages based on lithology and weathering. Values for the mineralisation assigned in the block were between 2.29t/m3 and 2.35t/m3 for weathered material and were between 2.35t/m3 and 2.67t/m3 for fresh mineralisation. Average waste densities were assigned based on lithology and weathering from measurements.

Mining and Metallurgical Methods and Parameters

It is assumed that the Mt Dromedary deposit can be mined using open pit techniques.

The Mt Dromedary deposit comprises natural graphite that has been demonstrated to be able to be processed by standard flotation technology to international bench mark product categories. Samples from the Central Zone were sent for Locked Cycle Testwork at JKTech in Brisbane, Queensland, to determine processing recoveries and concentrate grades for weathered and primary material. Results indicate that an approximate 93% processing recovery is achievable for primary material and an approximate 85% processing recovery is achievable for weathered material, producing a 95% graphitic very fine carbon concentrate.

Flake concentrate is likely suitable for anode material for lithium-ion batteries. Testwork was conducted by NOVONIX Battery Testing Services and confirmed a 95% TGC concentrate grade.

Cut-off Grade

The Mt Dromedary Mineral Resource has been constrained by the mineralisation solids and is reported above a cut-off grade of 5% TGC. The Mt Dromedary MRE at various TGC cut-off grades are shown in Table 3 below:

Table 3 – Mt Dromedary Deposit Mineral Resource Estimate at Various TGC Cut-Off Grades

| Grade | Incremental Resource | Cut-off | Cumulative Resource | ||||

| Range | Tonnage | TGC | Contained | Grade | Tonnage | TGC | Contained |

| TGC% | t | % | Graphite (t) | TGC% | t | % | Graphite (t) |

| 0.5 -> 1.0 | 9,321 | 0.96 | 90 | 0.5 | 18,727,920 | 10.87 | 2,036,420 |

| 1.0 -> 1.5 | 41,946 | 1.29 | 540 | 1.0 | 18,718,599 | 10.88 | 2,036,331 |

| 1.5 -> 2.0 | 218,497 | 1.73 | 3,783 | 1.5 | 18,676,653 | 10.90 | 2,035,791 |

| 2.0 -> 2.5 | 988,593 | 2.24 | 22,130 | 2.0 | 18,458,156 | 11.01 | 2,032,008 |

| 2.5 -> 3.0 | 1,070,574 | 2.74 | 29,322 | 2.5 | 17,469,563 | 11.50 | 2,009,879 |

| 3.0 -> 3.5 | 1,019,098 | 3.24 | 32,985 | 3.0 | 16,398,989 | 12.07 | 1,980,557 |

| 3.5 -> 4.0 | 1,055,065 | 3.74 | 39,420 | 3.5 | 15,379,891 | 12.66 | 1,947,572 |

| 4.0 -> 4.5 | 871,861 | 4.24 | 37,009 | 4.0 | 14,324,826 | 13.32 | 1,908,152 |

| 4.5 -> 5.0 | 799,013 | 4.75 | 37,926 | 4.5 | 13,452,965 | 13.90 | 1,871,143 |

| 5.0 -> 6.0 | 2,009,463 | 5.52 | 111,019 | 5.0 | 12,653,952 | 14.48 | 1,833,217 |

| 6.0 -> 7.0 | 1,031,876 | 6.44 | 66,442 | 6.0 | 10,644,489 | 16.17 | 1,722,198 |

| 7.0 -> 8.0 | 470,858 | 7.36 | 34,643 | 7.0 | 9,612,613 | 17.22 | 1,655,756 |

| 8.0 -> 9.0 | 317,892 | 8.56 | 27,209 | 8.0 | 9,141,755 | 17.73 | 1,621,113 |

| 9.0 -> 10.0 | 340,189 | 9.23 | 31,408 | 9.0 | 8,823,863 | 18.06 | 1,593,903 |

| 10.0 -> 11.0 | 39,185 | 10.49 | 4,110 | 10.0 | 8,483,674 | 18.41 | 1,562,495 |

| 11.0 -> 12.0 | 357,750 | 11.81 | 42,259 | 11.0 | 8,444,489 | 18.45 | 1,558,385 |

| 12.0 -> 13.0 | 208,610 | 12.30 | 25,654 | 12.0 | 8,086,739 | 18.74 | 1,516,126 |

| 13.0 -> 14.0 | 524,238 | 13.61 | 71,342 | 13.0 | 7,878,129 | 18.91 | 1,490,473 |

| 14.0 -> 15.0 | 504,882 | 14.52 | 73,328 | 14.0 | 7,353,891 | 19.29 | 1,419,131 |

| 15.0 -> 16.0 | 773,856 | 15.36 | 118,856 | 15.0 | 6,849,009 | 19.64 | 1,345,803 |

| 16.0 -> 17.0 | 849,501 | 16.54 | 140,546 | 16.0 | 6,075,153 | 20.19 | 1,226,948 |

| 17.0 -> 18.0 | 861,024 | 17.46 | 150,296 | 17.0 | 5,225,652 | 20.78 | 1,086,402 |

| 18.0 -> 19.0 | 912,615 | 18.49 | 168,702 | 18.0 | 4,364,628 | 21.44 | 936,106 |

| 19.0 -> 20.0 | 709,130 | 19.46 | 138,030 | 19.0 | 3,452,013 | 22.22 | 767,404 |

| 20.0 -> 22.5 | 1,378,710 | 21.43 | 295,426 | 20.0 | 2,742,883 | 22.93 | 629,374 |

| 22.5 -> 25.0 | 1,001,273 | 23.81 | 238,391 | 22.5 | 1,364,173 | 24.44 | 333,948 |

| 25.0 -> 27.5 | 340,410 | 26.19 | 89,151 | 25.0 | 362,900 | 26.19 | 95,557 |

| 27.5 -> 30.0 | 22,490 | 28.48 | 6,406 | 27.5 | 22,490 | 28.48 | 6,406 |

About NOVONIX Limited (ASX:NVX)

NOVONIX (then known as Graphitecorp Limited) completed its IPO and admission to ASX in December 2015 as the developer of the Mt Dromedary Graphite Project.[10] The Company changed its name to NOVONIX in July 2017 after completing the acquisition of NOVONIX Battery Testing Services, Inc. and establishment of the PUREgraphite anode material joint venture in North America.[11]

NOVONIX is now a leading battery materials and technology company aiming to revolutionise the global lithium-ion battery industry with innovative, sustainable technologies, high-performance materials, and more efficient production methods. NOVONIX manufactures industry-leading battery cell testing equipment, is growing its high-performance synthetic graphite anode material manufacturing operations, and has developed an all-dry, zero-waste cathode synthesis process. Through advanced R&D capabilities, proprietary technology, strategic partnerships, and as a leading North American supplier of battery-grade synthetic graphite, NOVONIX has gained a prominent position in the electric vehicle (EV) and energy storage systems (ESS) battery industry and is working to power a cleaner energy future. To learn more, visit us at www.novonixgroup.com or on LinkedIn and X.

About Lithium Energy Limited (ASX:LEL)

Lithium Energy Limited is an ASX listed battery minerals company which is developing its flagship Solaroz Lithium Brine Project in Argentina and the Burke and Corella Graphite Projects in Queensland. The Solaroz Lithium Project (LEL:90%) comprises 12,000 hectares of highly prospective lithium mineral concessions (where a JORC Indicated and Inferred Mineral Resource of lithium has been delineated) located strategically within the Salar de Olaroz Basin in South America’s “Lithium Triangle” in north-west Argentina. Lithium Energy shares the lithium rights in the Olaroz Salar basin with lithium carbonate producers Arcadium Lithium plc (ASX:LTM) and Lithium Argentina Corporation (TSX:LAAC). Prior to the announced sale of the Solaroz Project (settlement pending), Lithium Energy had completed a Scoping Study on Solaroz and had been investigating the development of a 20/40ktpa lithium carbonate equivalent (LCE) production facility using conventional evaporation ponds; the Company has also been evaluating direct-lithium extraction (DLE) technologies. The Burke and Corella Graphite Projects (LEL:100%) in Queensland, Australia, contains high grade JORC Indicated and Inferred Mineral Resources of graphite.

On 3 April 2024, Lithium Energy and NOVONIX Limited (ASX:NVX) announced the merger of their adjoining Burke and Mt Dromedary Queensland Natural Graphite Deposits into Lithium Energy subsidiary, Axon Graphite Limited (Proposed ASX Code: AXG), which will undertake a $15M to $25M IPO and seek admission to ASX as a dedicated vertically-integrated mine to Battery Anode Material (BAM) product manufacturing company. On 30 April 2024, Lithium Energy announced the sale of its interest in the Solaroz Project to a subsidiary of CNGR Advanced Materials Co Ltd for US$63 Million (~A$97 Million) cash; completion is subject to the satisfaction (or waiver, as applicable) of a number of conditions precedent, including receipt of regulatory approvals (in China and Argentina, as required) and receipt of environmental and concession related approvals relating to Solaroz. Pending completion of the sale of Solaroz, Lithium Energy will focus on advancing the Axon Graphite IPO and continuing to advance operations at Solaroz, including securing the relevant approvals required to satisfy applicable conditions precedent to the sale.

AUTHORISED FOR RELEASE

This Joint Announcement has been authorised for release by:

- NOVONIX Chairman, Admiral Robert J. Natter, USN Ret.

- Lithium Energy Chairman, William Johnson

FOR FURTHER INFORMATION:

| NOVONIX Limited (ASX:NVX) | Lithium Energy Limited (ASX:LEL) |

| Investors: Scott Espenshade | William Johnson |

| ir@novonixgroup.com | Executive Chairman |

| Media: Stephanie Reid, | +61 8 9214 9737 |

| media@novonixgroup.com | chair@lithiumenergy.com.au |

JORC CODE (2012) COMPETENT PERSONS’ STATEMENTS

- The information in this document that relates to Mineral Resources in relation to the Mt Dromedary Graphite Project is based on information compiled by Mr Shaun Searle. Mr Searle is a Member of the Australasian Institute of Geoscientists (AIG) and an employee of Ashmore Advisory Pty Ltd, an independent consultant to Axon Graphite Limited (being a subsidiary of Lithium Energy Limited). Mr Searle has sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration and to the activity being undertaken to qualify as a Competent Person as defined in the 2012 Edition of the ‘Australasian Code for the Reporting of Exploration Results, Mineral Resources and Ore Reserves’ (JORC Code). Mr Searle consents to the inclusion in this document of the matters based on his information in the form and context in which it appears.

- The information in this document that relates to Exploration Results in relation to the Burke and Corella Graphite Projects is based on information compiled by Mr Peter Smith, BSc (Geophysics) (Sydney) AIG ASEG. Mr Smith is a Member of AIG and a Director of Lithium Energy Limited. Mr Smith has sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration and to the activity being undertaken to qualify as a Competent Person as defined in the JORC Code. Mr Smith consents to the inclusion in this document of the matters based on his information in the form and context in which it appears.

- The information in this document that relates to Mineral Resources in relation to the Burke and Corella Graphite Projects is extracted from the following ASX market announcements made by Lithium Energy Limited dated:

The information in the original announcements is based on information compiled by Mr Shaun Searle, a Competent Person who is a Member of the AIG. Mr Searle is an employee of Ashmore Advisory Pty Ltd, an independent consultant to Lithium Energy Limited. Mr Searle has sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration and to the activity being undertaken to qualify as a Competent Person as defined in the JORC Code. Lithium Energy Limited confirms that it is not aware of any new information or data that materially affects the information included in the original market announcements (referred to above). Lithium Energy Limited confirms that the form and context in which the Competent Person’s findings are presented have not been materially modified from the original market announcements (referred to above).

CAUTIONARY NOTES REGARDING FORWARD-LOOKING STATEMENTS

NOVONIX Limited

This communication contains forward-looking statements about the company and the industry in which we operate. Forward-looking statements can generally be identified by use of words such as “anticipate,” “believe,” “contemplate,” “continue,” “could,” “estimate,” “expect,” “intend,” “may,” “plan,” “potential,” “predict,” “project,” “should,” “target,” “will,” or “would,” or other similar expressions. Examples of forward-looking statements in this communication include statements we make regarding the proposed transaction with Lithium Energy Limited and the proposed Axon Graphite Limited IPO and ASX listing, Axon’s development of the Mt. Dromedary, Burke and Corella natural graphite resources for the production of anode materials for EV batteries, and Axon’s ability to scale-up production of its battery anode materials. We have based these forward-looking statements on our current expectations and projections about future events and trends that we believe may affect our financial condition, results of operations, business strategy and financial needs. Such forward-looking statements involve and are subject to known and unknown risks, uncertainties and other factors which may cause our actual results, performance or achievements to be materially different from any future results, performance or achievements expressed or implied by the forward-looking statements. Factors that could affect our business and results are included in our filings with the U.S. Securities and Exchange Commission (“SEC”), including the Company’s Form 20-F. Copies of these filings may be obtained by visiting our Investor Relations website at www.novonixgroup.com or the SEC’s website at www.sec.gov.

Forward-looking statements are not guarantees of future performance or outcomes, and actual performance and outcomes may differ materially from those made in or suggested by the forward-looking statements contained in this communication. Accordingly, you should not place undue reliance on forward-looking statements. Any forward-looking statement in this communication is based only on information currently available to us and speaks only as of the date on which it is made. We undertake no obligation to publicly update any forward-looking statement, whether written or oral, that may be made from time, whether as a result of new information, future developments or otherwise, except as required by law. In particular, we caution that the proposed Axon IPO and ASX listing may be subject to final board and regulatory approvals and is dependent on market conditions. We caution that the admission of Axon to the official list of the ASX is conditional on and subject to the ASX’s satisfaction that Axon has a structure and operations suitable for a listed entity at the ASX’s absolute discretion. In accordance with section 734(5)(b) of the Corporations Act 2001 (Cth) (Corporations Act), it is noted that:

- Axon will be the offeror of fully paid ordinary shares under the IPO;

- a prospectus will be issued by Axon in accordance with Part 6.2 of the Corporations Act when the IPO shares are offered;

- a person should consider the prospectus in deciding whether to apply for IPO shares; and

- anyone who wants to apply for the IPO will need to complete an application form that will be in or will accompany the prospectus.

Lithium Energy Limited

This document contains “forward-looking statements” and “forward-looking information”, including statements and forecasts which include without limitation, expectations regarding future performance, costs, production levels or rates, mineral reserves and resources, the financial position of Lithium Energy, industry growth and other trend projections. Often, but not always, forward-looking information can be identified by the use of words such as “plans”, “expects”, “is expected”, “is expecting”, “budget”, “scheduled”, “estimates”, “forecasts”, “intends”, “anticipates”, or “believes”, or variations (including negative variations) of such words and phrases, or state that certain actions, events or results “may”, “could”, “would”, “might”, or “will” be taken, occur or be achieved. Such information is based on assumptions and judgements of management regarding future events and results. The purpose of forward-looking information is to provide the audience with information about management’s expectations and plans. Readers are cautioned that forward-looking information involves known and unknown risks, uncertainties and other factors which may cause the actual results, performance or achievements of Lithium Energy and/or its subsidiaries to be materially different from any future results, performance or achievements expressed or implied by the forward-looking information. Such factors include, among others, changes in market conditions, future prices of minerals/commodities, the actual results of current production, development and/or exploration activities, changes in project parameters as plans continue to be refined, variations in grade or recovery rates, plant and/or equipment failure and the possibility of cost overruns. Forward-looking information and statements are based on the reasonable assumptions, estimates, analysis and opinions of management made in light of its experience and its perception of trends, current conditions and expected developments, as well as other factors that management believes to be relevant and reasonable in the circumstances at the date such statements are made, but which may prove to be incorrect. Lithium Energy believes that the assumptions and expectations reflected in such forward-looking statements and information are reasonable. Readers are cautioned that the foregoing list is not exhaustive of all factors and assumptions which may have been used. Lithium Energy does not undertake to update any forward-looking information or statements, except in accordance with applicable securities laws.

ANNEXURE A

JORC CODE (2012 EDITION)

CHECKLIST OF ASSESSMENT AND REPORTING CRITERIA

FOR EXPLORATION RESULTS

Section 1 – Sampling Techniques and Data

| Criteria | JORC Code explanation | Commentary |

| Sampling techniques | · Nature and quality of sampling (eg cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc). These examples should not be taken as limiting the broad meaning of sampling.

· Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used. · Aspects of the determination of mineralisation that are Material to the Public Report. In cases where ‘industry standard’ work has been done this would be relatively simple (eg ‘reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay’). In other cases more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (eg submarine nodules) may warrant disclosure of detailed information. |

Sampling Methodology – Reverse Circulation (RC) Drilling

Sampling for the Phase 2 (2015) and Phase 3 (2016) drilling programs were relatively straightforward, as the UDR650 drill rig was fitted with a combined Cyclone-Splitter unit, unlike the Phase 1 (2015) drilling program, which required a dedicated separate Splitter unit. Both small geochemical assay and large bulk samples were collected from each 1-metre drilled from the side-mounted cyclone. A sample number tag was placed in the small geochemical assay sample bag and the contents weighed on digital scales. The weights were used to provide a rough bulk density for each 1m interval. Geophysical parameters were measured routinely from each 1m interval by probing the small geochemical assay sample bag with various instrumentation, including magnetic susceptibility (SI units), electrical conductivity (ohms) and gamma radiation (counts per second). A separate 2m “Composited Sample” was collected by extracting sub samples from 2 contiguous large bulk sample bags and placed into a numbered sample bag together with a tag number. Sampling Methodology – Diamond Core Drilling Detailed geochemical sampling was routinely conducted on a 1-metre interval basis of Quarter-Split HQTT drill core, collected from the Phase 2 and 3 drilling programs. This comprehensive sampling is regarded as more representative statistically. The HQTT Drill Core was initially split 50% using a diamond core saw cutting machine. Half-split core is being retained initially as a visual reference or for use as a bulk metallurgical sample. The remaining Half-Core was then split 50% into Quarter-Core, again using a manual core saw. The Quarter-Split Core was routinely submitted for geochemical analysis. The remaining Quarter-Split Core was used as a metallurgical sample. Selective Petrological sampling of some lithological units identified in drill core was undertaken. These petrology samples are by necessity a small sample, but were selected on the basis of being “typical” of the lithological unit from which they were collected. |

| Drilling techniques | · Drill type (eg core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc) and details (eg core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc).

|

Diamond Core

HQ Triple Tube diamond core was technically selected as the optimum sampling method for drilling the graphite mineralised zones at Mt Dromedary, on the basis of maximising recovery of graphite, as the method minimises disturbance to core, limiting potential losses in drilling water. The ground conditions at Mt Dromedary were expected to be initially poor down to 20m depth, due to surface weathering overprinting effects of the Tertiary regolith. The soft, lubricating nature of graphite and its property as a natural “floater”, together with the regolith clay weathering profile indicate triple tube core barrels should be employed. The HQ diameter core also permits a large representative sample to be recovered, maximising the potential for geological information, geochemical sampling, geotechnical data collection and offers a large metallurgical sample size potential from each metre interval. DEPCO Drilling Pty Ltd of Rockhampton, Queensland, was contracted by NOVONIX Limited (then known as GraphiteCorp Pty Ltd) (NOVONIX) to undertake the diamond drilling program in November 2015. DEPCO Drilling supplied a UDR650 multi-purpose drill rig. Subsequently, Calibre Drilling Pty Ltd of Cloncurry was contracted by NOVONIX to assist with diamond core drilling due to delays experienced with DEPCO Drilling. Calibre Drilling supplied a small track-mounted Cortech YDX-3L diamond drill rig. The rig used a standard HQ diamond drill bit and was not fitted for triple tube core barrels. Reverse Circulation DEPCO Drilling was contracted by NOVONIX to undertake the RC drilling program in November 2015. DEPCO Drilling supplied a UDR650 multi-purpose drill rig. The RC hammer bit had a measured diameter of 123mm. A larger diameter RC hammer was used to drill an initial pre-collar of 4m in the soil-colluvium profile, which was then cased off using PVC pipe to avoid unconsolidated material falling behind the drill rods. A combined Cyclone and Sample Splitter unit was fitted to the side of the UDR650 drill rig. The Cyclone collected a 75% bulk sample in a big plastic bag and a 25% sample in a small plastic bag. |

| Drill sample recovery | · Method of recording and assessing core and chip sample recoveries and results assessed.

· Measures taken to maximise sample recovery and ensure representative nature of the samples. · Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material. |

Diamond Drill Core recovery was routinely recorded every metre. Initial core recoveries were typically 70-95% in the initial 20m, but as each drill hole progressed beyond 20m depth, core recovery typically increased to 100%.

Core recoveries recorded within graphite mineralised zones were typically >85%. |

| Logging | · Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies.

· Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc) photography. · The total length and percentage of the relevant intersections logged. |

Logging – Drill Core

Once the drilling was completed, all the drill core was removed from site to Chinalco Yunnan Copper Resources Limited Mt Isa core processing facility, hired by NOVONIX. A standardised sequential logging, processing and sampling procedure was employed for the HQ drill core on a 1-metre basis. The data was computer-coded for digital plotting purposes. Core was initially cleaned to remove drill mud and greases. The core was then orientated using “Top of Core” marks from the Reflex orientation tool, marked into 1m intervals and the core recovery recorded. The core was then photographed using high-resolution digital camera and then geologically logged. Geological logging of Drill Core was routinely undertaken on a systematic one-metre interval basis, recording the following geological data: § Core Recovery. § Rock Code. § Colour. § Minerals. § Texture. § Hardness. § Oxidation %. § Alteration. Mineralogy & %. § Sulphide. Mineralogy & %. § Veining. Mineralogy & %. § Graphite Content. Geotechnical data was collected, including Rock Quality Designation (RQD), Fracture Density and orientations of structures such as faults, fractures, joints, foliation, bedding, veins recorded. Geophysical properties of the core were collected, with magnetic susceptibility, electrical conductivity and Gamma radiation counts per second recorded. The Specific Gravity for each interval was collected using an Archimedes Principle water displacement device. Metallurgical samples were determined by Ore Type and selected on the basis of lithology and weathering/primary characteristics. Abrasion/UCS Engineering, Comminution and MLA samples were then sampled from the core. The core was then split into one half and then into 2x quarters using a manual core saw. One ¼ split core was used for geochemical analysis and the other ¼ split core used for bulk Variability metallurgical testing. The Core Trays (with balance of remaining half-split core) are currently stored on pallets in Chinalco’s Core Shed facility. The remaining core can be resampled and/or used in future metallurgical testwork if required. Logging – RC Drilling Geological logging of reverse circulation drill chips was routinely undertaken for each 1-metre interval using similar procedures to core logging (described above). Visual record samples were collected from the large bulk sample and contents placed into a 20-compartment plastic tray. Each chip tray was photographed using a high-resolution digital camera. |

| Sub-sampling techniques and sample preparation | · If core, whether cut or sawn and whether quarter, half or all core taken.

· If non-core, whether riffled, tube sampled, rotary split, etc and whether sampled wet or dry. · For all sample types, the nature, quality and appropriateness of the sample preparation technique. · Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples. · Measures taken to ensure that the sampling is representative of the in situ material collected, including for instance results for field duplicate/second-half sampling. · Whether sample sizes are appropriate to the grain size of the material being sampled. |

One-metre intervals of Quarter-Split Drill Core and RC Drill Chips were submitted into ALS Minerals sample preparation laboratory in Mount Isa, Queensland. Geochemical analysis was subsequently performed at ALS Minerals laboratory in Brisbane, Queensland.

Geochemical analysis was by analytical Method C-IR 18 Total Graphitic Carbon, Method C-IR07 Total Carbon, Method S-IR08 Total Sulphur, Method Ash-01 Ash Content and Method ME-GRA05g Loss on Ignition. Multi-element geochemical analyses were performed on 2-metre composites of RC Drill Chips and selected intervals of the graphite mineralized zones. The Multi-element analyses included whole rock oxides by Method ME-ICP06 Major Oxides, trace elements by Method ME-MS81 Ultra Trace Level, base metals by Method ME-ACD81 Four Acid Digest and Method ME-MS41 Ultra Trace Level Method. Representative grab samples (approximately 200g weight) of the various Ore Types were collected from drill core on the basis of 1 sample per 10m and forwarded to ACTLABS (Ancaster, Canada) for Mineral Liberation Analysis (MLA). |

| Quality of assay data and laboratory tests | · The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total.

· For geophysical tools, spectrometers, handheld XRF instruments, etc, the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc. · Nature of quality control procedures adopted (eg standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (ie lack of bias) and precision have been established. |

Geochemical Analysis

One-metre intervals of Quarter-Split Drill Core and RC Drill Chips were submitted into ALS Minerals sample preparation laboratory in Mount Isa, Queensland. Geochemical analysis was subsequently performed at ALS Minerals laboratory in Brisbane, Queensland. Geochemical analysis was by analytical Method C-IR 18 Total Graphitic Carbon, Method C-IR07 Total Carbon, Method S-IR08 Total Sulphur, Method Ash-01 Ash Content and Method ME-GRA05g Loss on Ignition. Accuracy levels are reported to 0.01%. Multi-element geochemical analyses were performed on 2-metre composites of RC Drill Chips and selected intervals of the graphite mineralised zones. The Multi-element analyses included whole rock oxides by Method ME-ICP06 Major Oxides, trace elements by Method ME-MS81 Ultra Trace Level, base metals by Method ME-ACD81 Four Acid Digest and Method ME-MS41 Ultra Trace Level Method. The QA/QC results confirm the suitability of the drilling data for use in resource estimation. Mineral Liberation Analyser Representative samples of the various Ore Types were analysed by ACTLABS (Ancaster, Canada) for Mineral Liberation Analysis (MLA), to determine the modal mineralogy and characterise the size and deportment of graphite flakes. The MLA is a quantitative mineralogical technology, developed by ACTLABS, which uses a FEI Quanta600F scanning electron microscope (“SEM”). A Jones Riffle splitter was used to split a representative sample for the MLA study. The samples were further screened to -850/+106 µm. Representative splits were taken using a Quantachrome Mini-riffler and mixed with carnauba wax. Each sample was mounted on an epoxy resin block and coated with carbon and then polished, prior to examination using the MLA. The +106/-850 µm fraction range was measured for the graphite flake size distribution, in order to represent preserved rock fragments that are closest to the original graphite size and rock texture. Mineral matter was identified and quantified using the XBSE measurement mode on the Quanta 600F MLA instrument. Minerals and other attributes are directly measured on the MLA by a combination of image analysis, employing atomic number contrast imaging from back-scattered electron (BSE) signal intensity and Energy Dispersive Spectrometry (EDS), using two Bruker 5010 SDD detectors. The BSE signal intensity is proportional to the mean atomic number of minerals. |

| Verification of sampling and assaying | · The verification of significant intersections by either independent or alternative company personnel.

· The use of twinned holes. · Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols. · Discuss any adjustment to assay data. |

The QA/QC protocols adopted for the Mt Dromedary Phase 2 drilling program involved routinely inserting a Certified Graphite Reference Standard (5 different Standards used) or Blank sample into the tag book number sequence every 10 samples. A total of 278 Certified Reference Materials and 45 Blank samples were used.

The QA/QC sample density is considered to be more than adequate and is very robust. Additional QA/QC controls were also provided by internal laboratory repeats and standards. Laboratory performance and all reported analytical results was statistically evaluated using QA/QC monitoring software. All Certified Reference Materials reported within 1 Standard Deviation of the Certified value. Two (2) of the Blank samples indicated very low order graphite contamination (<0.05% Cg). |

| Location of data points | · Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation.

· Specification of the grid system used. · Quality and adequacy of topographic control. |

M.H. Lodewyk Pty Ltd licensed surveyors of Mount Isa, Queensland, were contracted to establish a series of fixed Base Stations on site and then accurately survey each drill hole collar to sub-metre accuracy, using a Differential Positioning System (DGPS) instrument, in the MGA 94 Zone 54 projection.

Down hole surveys were routinely collected every 30m, using a Reflex EZ Shot after completion of End of Hole Depth on the way out of the hole, and sequentially as the drill rod string was recovered. Down hole survey data was also collected continuously and automatically by the High Resolution Acoustic Televiewer down hole instrument supplied by Geology Pty Ltd of Hervey Bay. Down hole survey data was collected with an accuracy of ±0.01 degrees and ±0.01m. |

| Data spacing and distribution | · Data spacing for reporting of Exploration Results.

· Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied. · Whether sample compositing has been applied. |

Data was routinely collected on a continuous 1m interval basis. Samples were collected at 1m intervals down each hole. |

| Orientation of data in relation to geological structure | · Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type.

· If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias, this should be assessed and reported if material. |

Drill Hole Orientation

Drill holes were designed to intersect graphite mineralisation at perpendicular to strike observed in outcrop. Geotechnical data, automatically collected by the High Resolution Acoustic Televiewer and classified by software confirms the foliation structures and indicate data collected from drill core is generally conformable with the schistose fabric foliation of the graphite mineralisation. Core Orientation Core orientation was routinely undertaken during drilling using a Reflex ACT II tool. The unit is attached to the top of the core inner tube barrel and initialised. The unit is removed and the orientation marked on the Top of Core using a coloured paint marker or chinagraph pencil. |

| Sample security | · The measures taken to ensure sample security. | All the samples collected were placed into plastic bags and securely sealed with staples. The sample bags were then placed in a large plastic bag labelled accordingly with Hole Number and Sample Type and sealed with plastic ties. The various samples were placed separately into 1-tonne capacity Bulka Bags and stored temporarily on site before being transported by 8-tonne capacity Flat Bed Truck direct into ALS Minerals Division preparation laboratory facility in Mount Isa, Queensland. A follow up visit to the ALS Minerals Division preparation laboratory facility in Mount Isa indicated no tampering with the staple-sealed sample bags had occurred. |

| Audits or reviews | · The results of any audits or reviews of sampling techniques and data. | Drilling and sampling procedures were reviewed by independent consultants during a site visit in 2015, who found that all procedures and practices conformed to industry standards. |

Section 2 Reporting of Exploration Results

Section 3 – Estimation and Reporting of Mineral Resources

| Criteria | JORC Code explanation | Commentary |

| Database integrity | · Measures taken to ensure that data has not been corrupted by, for example, transcription or keying errors, between its initial collection and its use for Mineral Resource estimation purposes.

· Data validation procedures used. |

The data base has been systematically audited by NOVONIX geologists.

All drilling data has been verified as part of a continuous validation procedure. Once a drill hole is imported into the data base a report of the collar, down-hole survey, geology, and assay data are produced. This is then checked by a NOVONIX geologist, and any corrections are completed by the data base manager. |

| Site visits | · Comment on any site visits undertaken by the Competent Person and the outcome of those visits.

· If no site visits have been undertaken indicate why this is the case. |

A site visit was conducted by Shaun Searle of Ashmore Advisory Pty Ltd (Ashmore) during January 2023. Mr Searle inspected the Mt Dromedary deposit area and sub-crop. During this site visit, notes and photos were taken. No major issues were encountered. |

| Geological interpretation | · Confidence in (or conversely, the uncertainty of) the geological interpretation of the mineral deposit.

· Nature of the data used and of any assumptions made. · The effect, if any, of alternative interpretations on Mineral Resource estimation. · The use of geology in guiding and controlling Mineral Resource estimation. · The factors affecting continuity both of grade and geology. |

The confidence in the geological interpretation is considered to be good and is based on visual confirmation in outcrop and within drill hole intersections.

Geochemistry and geological logging has been used to assist identification of lithology and mineralisation. The Mt Dromedary Project area is hosted by a mapped graphitic schist as a sub-unit of the Corella Formation, within the Mary Kathleen Group and is of Proterozoic age. The style of mineralisation is crystalline graphite within graphitic schists. Infill drilling has supported and refined the model and the current interpretation is considered robust. Observations of outcrops and host rocks as well as the results of infill drilling, confirm the geometry of the mineralisation. Infill drilling has confirmed geological and grade continuity. |

| Dimensions | · The extent and variability of the Mineral Resource expressed as length (along strike or otherwise), plan width, and depth below surface to the upper and lower limits of the Mineral Resource. | The Mt Dromedary Mineral Resource area extends over a north northeast – south southwest strike length of ~1km (from 7,830,510mN – 7,831,510mN), has a maximum width of ~130m (418,220mE – 418,350mE) and includes the ~120m vertical interval from 160mRL to 40mRL. |

| Estimation and modelling techniques | · The nature and appropriateness of the estimation technique(s) applied and key assumptions, including treatment of extreme grade values, domaining, interpolation parameters and maximum distance of extrapolation from data points. If a computer assisted estimation method was chosen include a description of computer software and parameters used.

· The availability of check estimates, previous estimates and/or mine production records and whether the Mineral Resource estimate takes appropriate account of such data. · The assumptions made regarding recovery of by-products. · Estimation of deleterious elements or other non-grade variables of economic significance (eg sulphur for acid mine drainage characterisation). · In the case of block model interpolation, the block size in relation to the average sample spacing and the search employed. · Any assumptions behind modelling of selective mining units. · Any assumptions about correlation between variables. · Description of how the geological interpretation was used to control the resource estimates. · Discussion of basis for using or not using grade cutting or capping. · The process of validation, the checking process used, the comparison of model data to drill hole data, and use of reconciliation data if available. |

Using parameters derived from modelled variograms, Ordinary Kriging (OK) was used to estimate average block grades in up to three passes using Surpac software. Linear grade estimation was deemed suitable for the Mt Dromedary Mineral Resource due to the geological control on mineralisation. Maximum extrapolation of wireframes from drilling was 50m along strike and 70m down-dip. This was half drill hole spacing in this region of the Mt Dromedary Project. Maximum extrapolation was generally half drill hole spacing.

Reconciliation could not be conducted due to the absence of mining. No recovery of by-products is anticipated. In addition to total graphitic carbon (TGC), total carbon (TC), S, LOI and Ash content were interpolated into the block model. The parent block dimensions used were 25m NS by 12.5m EW by 5m vertical with sub-cells of 6.25m by 3.125m by 1.25m. The parent block size dimension was selected on the results obtained from Kriging Neighbourhood Analysis that suggested this was the optimal block size for the dataset. An orientated ‘ellipsoid’ search was used to select data and adjusted to account for the variations in lode orientations, however all other parameters were taken from the variography derived from Objects 2 and 101. Three passes were used for each domain. The first pass had a range of 80, with a minimum of 4 samples. For the second pass, the range was extended to 150m, with a minimum of 4 samples. For the final pass, the range was extended to 300m, with a minimum of 4 samples. A maximum of 12 samples was used for all three passes. No assumptions were made on selective mining units. TGC had a strong positive correlation with TC and LOI. TC and LOI also had a strong positive correlation. Remaining pairs had no correlations or weak negative correlations. The Mt Dromedary deposit mineralisation was constrained by wireframes constructed using a nominal 1% TGC cut-off grade. For high grade mineralisation, a 10% TGC cut-off was used to construct the wireframes. The wireframes were applied as hard boundaries in the estimate. Statistical analysis was carried out on data from seven domains. After analysis, it was determined that no top-cuts were required. Validation of the model included detailed comparison of composite grades and block grades by northing and elevation. Validation plots showed good correlation between the composite grades and the block model grades. |

| Moisture | · Whether the tonnages are estimated on a dry basis or with natural moisture, and the method of determination of the moisture content. | Tonnages and grades were estimated on a dry in situ basis. |

| Cut-off parameters | · The basis of the adopted cut-off grade(s) or quality parameters applied. | The Mt Dromedary Mineral Resource estimate has been constrained by the mineralisation solids and reported above a cut-off grade of 5% TGC. Further geological, geotechnical, engineering and metallurgical studies are recommended to further define the graphite mineralisation. |

| Mining factors or assumptions | · Assumptions made regarding possible mining methods, minimum mining dimensions and internal (or, if applicable, external) mining dilution. It is always necessary as part of the process of determining reasonable prospects for eventual economic extraction to consider potential mining methods, but the assumptions made regarding mining methods and parameters when estimating Mineral Resources may not always be rigorous. Where this is the case, this should be reported with an explanation of the basis of the mining assumptions made. | Ashmore has assumed that the Mt Dromedary deposit could be mined using open pit mining techniques. |

| Metallurgical factors or assumptions | · The basis for assumptions or predictions regarding metallurgical amenability. It is always necessary as part of the process of determining reasonable prospects for eventual economic extraction to consider potential metallurgical methods, but the assumptions regarding metallurgical treatment processes and parameters made when reporting Mineral Resources may not always be rigorous. Where this is the case, this should be reported with an explanation of the basis of the metallurgical assumptions made. | The Mt Dromedary deposit comprises natural graphite that has been demonstrated to be able to be processed by standard flotation technology to international bench mark product categories. Samples from the Central Zone (of the Mt Dromedary deposit) were sent for Locked Cycle Testwork at JKTech in Brisbane, Queensland, to determine processing recoveries and concentrate grades for weathered and primary material. Results indicate that an approximate 93% processing recovery is achievable for primary material and an approximate 85% processing recovery is achievable for weathered material, producing a 95% graphitic (very fine) carbon concentrate.

Flake concentrate is likely suitable for anode material for lithium-ion batteries. Additional testwork was conducted by NOVONIX Battery Testing Services, Inc. and confirmed a 95% TGC concentrate grade. |

| Environmental factors or assumptions | · Assumptions made regarding possible waste and process residue disposal options. It is always necessary as part of the process of determining reasonable prospects for eventual economic extraction to consider the potential environmental impacts of the mining and processing operation. While at this stage the determination of potential environmental impacts, particularly for a greenfields project, may not always be well advanced, the status of early consideration of these potential environmental impacts should be reported. Where these aspects have not been considered this should be reported with an explanation of the environmental assumptions made. | No assumptions have been made regarding environmental factors. MDSTPL will work to mitigate environmental impacts as a result of any future mining or mineral processing. |

| Bulk density | · Whether assumed or determined. If assumed, the basis for the assumptions. If determined, the method used, whether wet or dry, the frequency of the measurements, the nature, size and representativeness of the samples.

· The bulk density for bulk material must have been measured by methods that adequately account for void spaces (vugs, porosity, etc), moisture and differences between rock and alteration zones within the deposit. · Discuss assumptions for bulk density estimates used in the evaluation process of the different materials. |

A total of 795 density measurements were taken from diamond drill core at the deposit, analysed using the dry weight / wet weight technique.

It is assumed there are minimal void spaces in the rocks within the deposit. Bulk densities were assigned averages based on lithology and weathering. Values for the mineralisation assigned in the block were between 2.29t/m3 and 2.35t/m3 for weathered material and were between 2.35t/m3 and 2.67t/m3 for fresh mineralisation. Average waste densities were assigned based on lithology and weathering from measurements. |

| Classification | · The basis for the classification of the Mineral Resources into varying confidence categories.

· Whether appropriate account has been taken of all relevant factors (ie relative confidence in tonnage/grade estimations, reliability of input data, confidence in continuity of geology and metal values, quality, quantity and distribution of the data). · Whether the result appropriately reflects the Competent Person’s view of the deposit. |

The Mt Dromedary Mineral Resource estimate is reported here in compliance with the 2012 Edition of the ‘Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves’ by the Joint Ore Reserves Committee (JORC Code). The Mt Dromedary Mineral Resource was classified as Indicated and Inferred Mineral Resources based on data quality, sample spacing, and lode continuity. The Indicated Mineral Resource was defined within areas of close spaced RC and diamond core drilling of predominantly 50m by 30m, and where the continuity and predictability of the lode positions was good, with some Indicated Mineral Resource classified where good grade continuity occurred up to 100m by 50m. The Inferred Mineral Resource was assigned to areas where drill hole spacing was greater than 100m by 50m, where small, isolated pods of mineralisation occur outside the main mineralised zones, and to geologically complex zones.

The input data is comprehensive in its coverage of the mineralisation and does not favour or misrepresent in-situ mineralisation. The definition of mineralised zones is based on high level geological understanding producing a robust model of mineralised domains. This model has been confirmed by infill drilling which supported the interpretation. Validation of the block model shows good correlation of the input data to the estimated grades. The Mt Dromedary Mineral Resource estimate appropriately reflects the view of Mr Shaun Searle (of Ashmore) as the Competent Person. |

| Audits or reviews | · The results of any audits or reviews of Mineral Resource estimates. | Internal audits have been completed by Ashmore which verified the technical inputs, methodology, parameters and results of the estimate. |

| Discussion of relative accuracy/ confidence | · Where appropriate a statement of the relative accuracy and confidence level in the Mineral Resource estimate using an approach or procedure deemed appropriate by the Competent Person. For example, the application of statistical or geostatistical procedures to quantify the relative accuracy of the resource within stated confidence limits, or, if such an approach is not deemed appropriate, a qualitative discussion of the factors that could affect the relative accuracy and confidence of the estimate.

· The statement should specify whether it relates to global or local estimates, and, if local, state the relevant tonnages, which should be relevant to technical and economic evaluation. Documentation should include assumptions made and the procedures used. · These statements of relative accuracy and confidence of the estimate should be compared with production data, where available. |

The geometry and continuity has been adequately interpreted to reflect the applied level of Indicated and Inferred Mineral Resource. The data quality is good and the drill holes have detailed logs produced by qualified geologists. A recognised laboratory has been used for all analyses.

The Mt Dromedary Mineral Resource statement relates to global estimates of tonnes and grade. |

[1] Axon Graphite Limited is currently a wholly-owned subsidiary of Lithium Energy

[2] Refer NVX ASX Announcement dated 3 April 2024: NOVONIX Limited and Lithium Energy Limited to Combine Natural Graphite Interests with Intention to Take Combined Business Public and LEL ASX Announcement dated 3 April 2024: Merger of Lithium Energy and NOVONIX Natural Graphite Assets and Proposed Axon Graphite Limited Spin-Out and IPO

[3] Refer NVX ASX Announcement dated 20 October 2016: Upgraded Independent JORC Mineral Resource Estimate

[4] Refer LEL ASX Announcement dated 5 April 2023: Burke Graphite Mineral Resource Upgrade Delivers Significant Increases in Size and Confidence

[5] Refer LEL ASX Announcement dated 16 June 2023: Maiden Corella Graphite Mineral Resource Delivers Doubling of Graphite Inventory

[6] Refer also NVX ASX Announcements dated 28 September 2018: 2018 Annual Report, 26 July 2018: Mount Dromedary Battery Materials Project Update – New Results, 20 October 2016: Upgraded Independent JORC Mineral Resource Estimate and 20 October 2016: Lithium-Ion Battery Physical & E-Chemical Suitability Tests

[7] Refer NVX ASX Announcement dated 1 December 2015: Graphitecorp Limited Replacement Prospectus dated 10 November 2015

[8] Refer NVX ASX Announcements dated 18 February 2016: Phase 2 Drilling Programme Results and 14 March 2016: Updated Independent JORC Mineral Resource Statement

[9] Refer NVX ASX Announcement dated 20 October 2016: Upgraded Independent JORC Mineral Resource Estimate

[10] Refer Graphitecorp Limited Prospectus dated 10 November 2015, released on ASX on 1 December 2015

[11] Refer NVX ASX Announcements dated 13 July 2017: Change of Name to NOVONIX Limited and 8 June 2017: Proposed Change of Company Name