Progress Demands Urgency

For any company dependent on the battery supply chain, whether sourcing cells for electric vehicles, qualifying novel materials or standing-up giga-factories, assessing cell quality, performance, and lifetime typically takes months to years of costly testing and is the single biggest bottleneck to energy storage innovation. But what if testing time was cut to a matter of weeks?

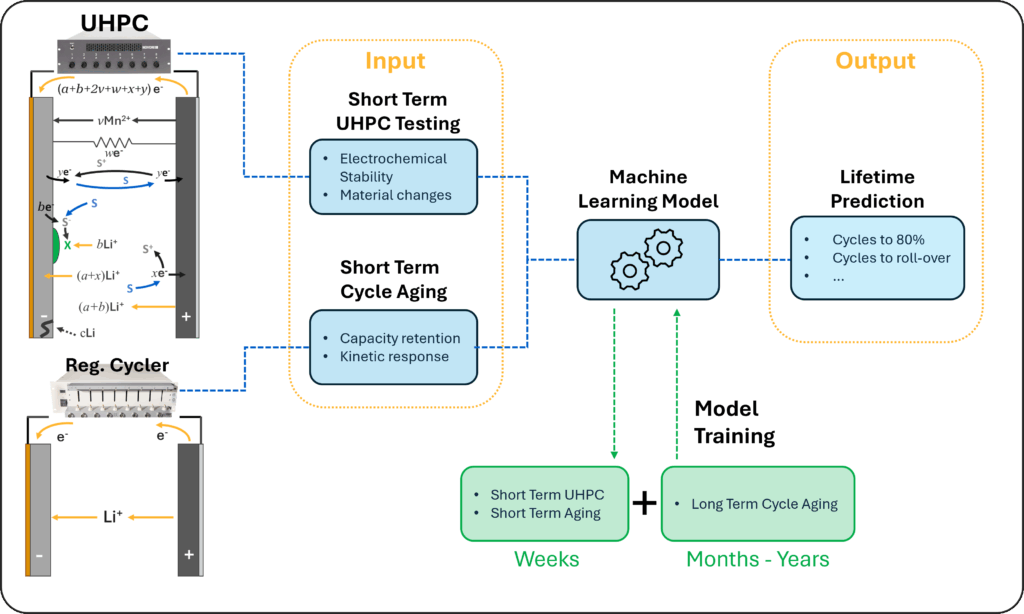

Degradation mechanisms in chemistries such as lithium-ion are non-trivial, often occurring at minuscule rates of reaction, making them difficult – or impossible – to capture on traditional spec cell testing equipment, requiring long-test times before differences are evident.1,2 This is where techniques utilizing Ultra-High Precision Coulometry (UHPC) cell testing equipment excels, and data-driven predictive models thrive.

Filling the gaps between traditional cell testing and complex and/or destructive analytical techniques, UHPC offers quantifiable insights into electrochemical mechanisms which are otherwise invisible using other techniques. This article explores how cell and auto OEMs, materials companies, and world-class institutions use UHPC to cut an order of magnitude off their testing times, and how high-fidelity UHPC data unlocks opportunities for predictive Machine Learning (ML) methods.

UHPC: A Brief Background

UHPC was pioneered by Prof. Jeff Dahn in 2010 with the goal of accurately detecting low-rate electrochemical degradation in lithium-ion cells.1-2

Since then, UHPC techniques have been published in hundreds of journal articles spanning many applications and chemistries. Prof. Dahn has primarily employed low-rate constant current cycling to accurately mitigate kinetic effects during cycling and accurately measure cycle metrics to correlate to long-term performance. However, a boundless list of techniques can benefit from the use of UHPC across the development lifecycle, from fundamental material synthesis work to quality control in mass manufacturing.

In 2013, following industry-wide demand for commercial cell testing equipment capable of UHPC techniques, Dr. Chris Burns and Dr. David Stevens, both mentored by Prof. Dahn, founded NOVONIX and commercialized the first market-ready UHPC cell testing product, which has evolved and spread across the battery industry over the last 12 years.

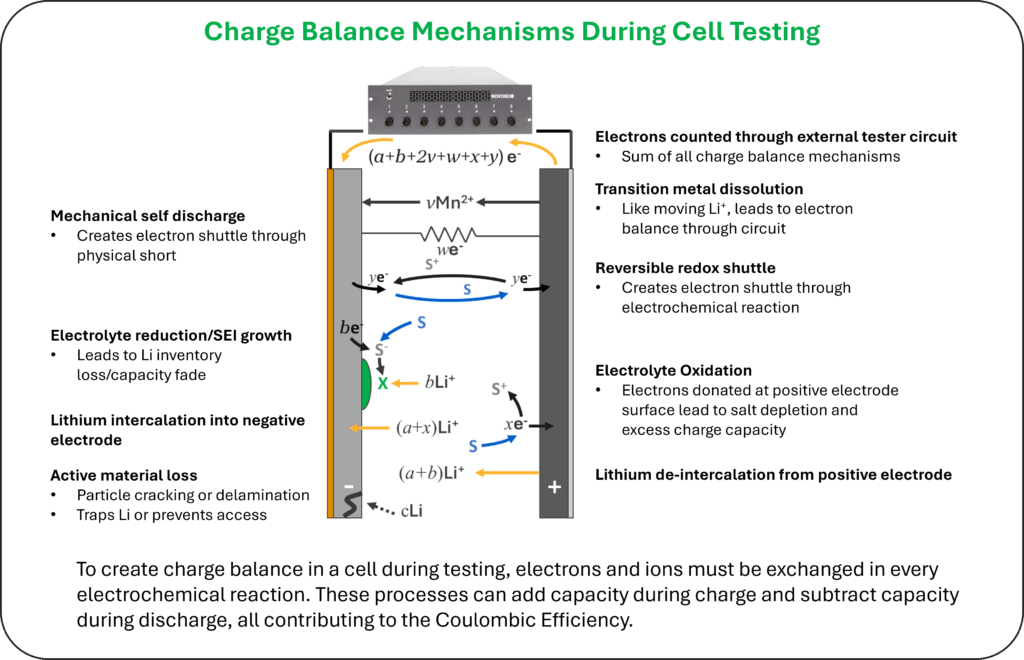

UHPC equipment requires the highest precision and accuracy possible to allow researchers to develop methods to understand specific electrochemical degradation mechanisms during cell testing and measure metrics such as coulombic efficiency accurate to 10s of ppm. These mechanisms involve cell materials such as anodes, cathodes, electrolytes, etc., exchanging electrons at electrode surfaces in complex reactions. As degradation occurs, the associated processes which create charge balance in the cell while undergoing testing cause tiny differences in charge and discharge capacity. These processes are shown in Figure 2 and include, but are not limited to:

- Electrolyte reduction and oxidation

- SEI formation

- Active material loss/particle cracking

- Transition metal dissolution

- Mechanical self-discharge

- Reversible redox shuttles

UHPC data can add a previously unattainable level of insight into cell chemistry and processes leading to end of life. These data therefore have important implications in the field of predictive analytics for batteries.

Battery Failure Prediction

A variety of methods are used to predict the lifetime of cells under various conditions. These include:

- Empirical aging models

- Qualitative ranking

- Physics-based models

- Machine learning

Each method has advantages and disadvantages. For example: empirical models can be iterated quickly but do not generalize well, qualitative ranking provides a holistic picture of cell degradation but requires subject-matter expertise and excessive time, physics-based models give detailed performance predictions but require extensive parametrization, and ML models provide broad predictions at low cost but typically require large training data sets.

To download the full case study on Ultra-High Precision Coulometry (UHPC) and Machine Learning from NOVONIX and SandboxAQ, complete the form below.

"*" indicates required fields