Batch-to-batch reproducibility is the capability of a manufacturing process to produce battery materials or cells with the same quality and performance across different production runs. In the battery industry, consistency is vital: each batch of materials, electrodes, electrolyte, and cells must meet strict specifications to ensure every battery performs consistently. Poor reproducibility can lead to variability of battery capacity, cycle life, or safety from one batch to another, undermining confidence in the product. Achieving high reproducibility requires tight control over material properties such as particle size, purity, etc., and processes including mixing, coating, cell assembly, formation, cell aging, etc., and the quality checks at each step.

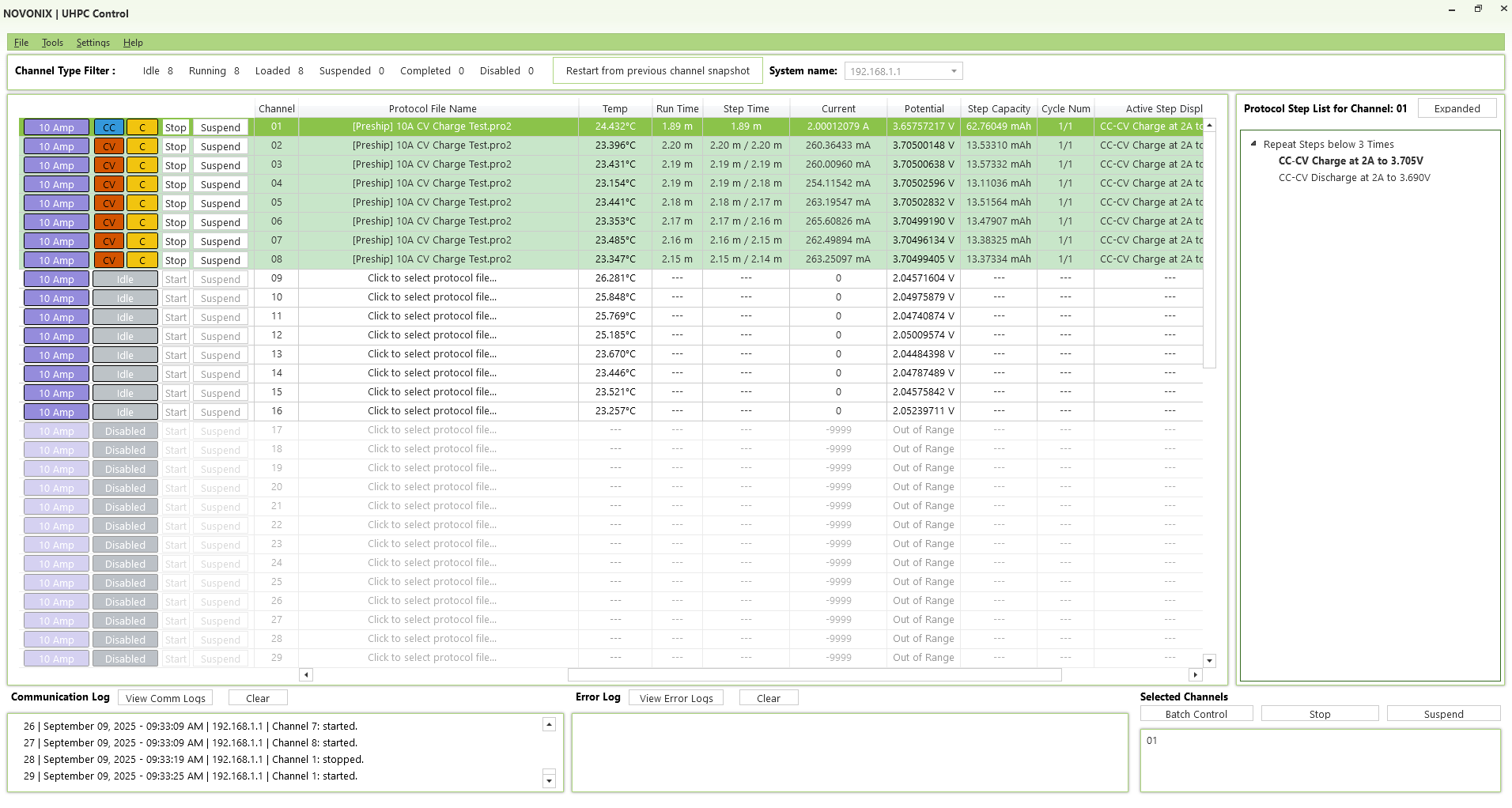

NOVONIX places a strong emphasis on batch-to-batch consistency in both its material production and when evaluating batteries for clients. Using advanced analytical techniques and precise testing equipment, including UHPC and other diagnostics, NOVONIX can detect even subtle performance variations between batches. This data-driven feedback allows processes to be fine-tuned for greater uniformity. Whether producing synthetic graphite anode material or assembling prototype cells on a pilot line, NOVONIX implements rigorous quality control protocols to ensure each batch meets the same high standards. By maintaining reproducibility, NOVONIX helps enable scale-up from pilot to mass production without sacrificing performance or reliability.