About NOVONIXTM Cathode Materials

NOVONIX has commissioned a 10 tonnes per annum (tpa) pilot scale facility to demonstrate the scalability of its patented all-dry, zero-waste cathode synthesis process for NMC cathode production. A commercial-scale process comparison study conducted by Hatch Ltd. estimated potential improvements over the conventional process:

Capital expense intensity estimated nearly 30% lower

Processing cost reductions estimated nearly 50% lower

Estimated power consumption improvements of approximately 27%

Removes the need for liquid in the material processing steps

Eliminates other key waste byproducts including sodium sulphate

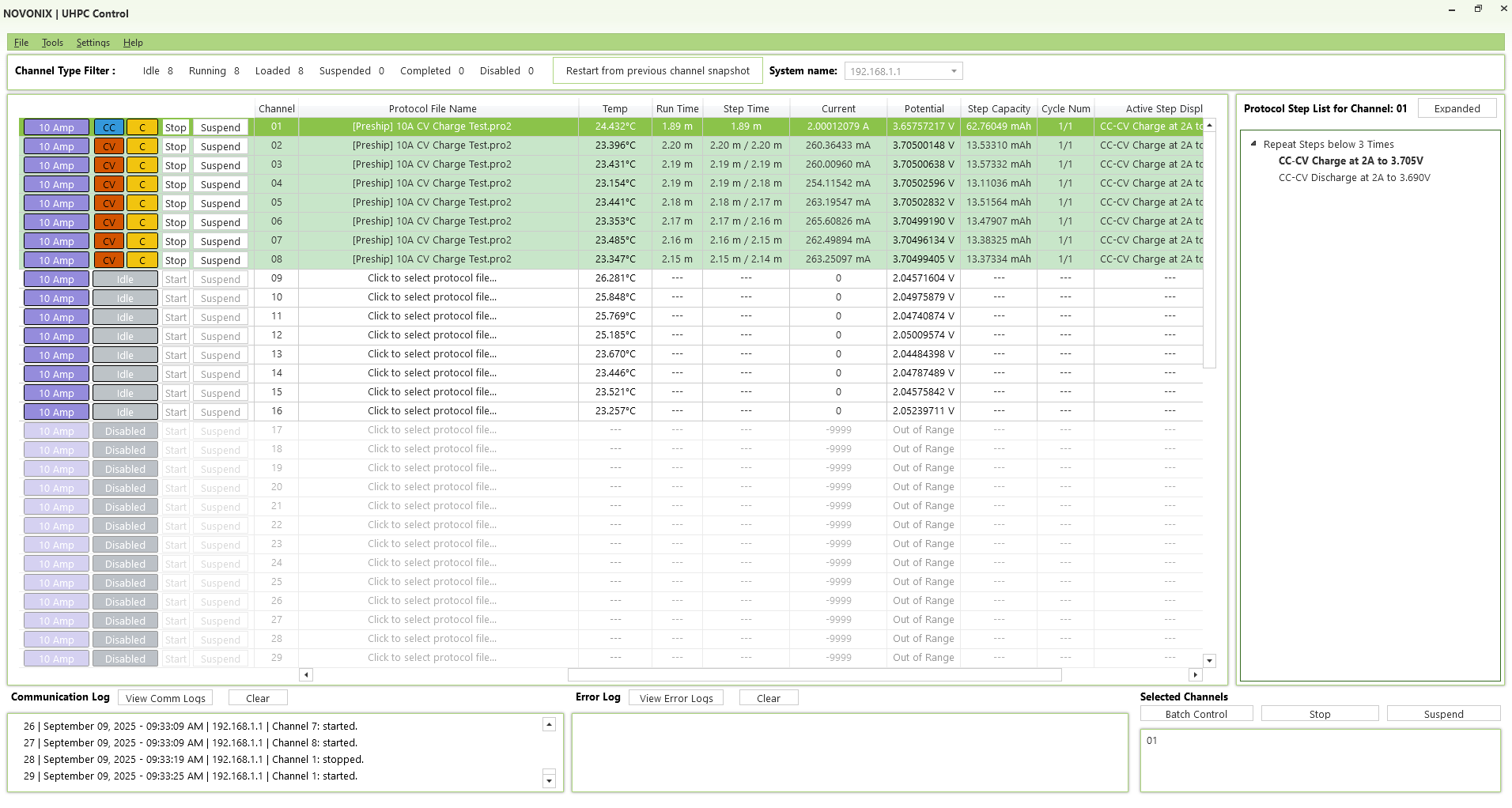

25°C; 2.8-4.3 V: 1.0C-Rate Cycling

- NOVONIX NMC 631

- Commercial NMC 631

1.2 M LiPF6 EC:EMC:DMC (25:5:70 wt. %) + 3 wt. % VC

0.05C cycle every 200 cycles

70 kPa (10 psi) clamp pressure

40°C; 2.8-4.3 V; 0.33C-Rate Cycling

- NOVONIX NMC 631

- Commercial NMC 631

1.2 M LiPF6 EC:EMC:DMC (25:5:70 wt. %) + 3 wt. % VC

0.05C cycle every 200 cycles

70 kPa (10 psi) clamp pressure

The pilot line, housed in a 3,200 m2 (35,000 sq. ft.) facility, allows NOVONIX to demonstrate large-scale production of up to 10 tpa.

Our all-dry, zero-waste cathode synthesis process:

NOVONIX holds foundational patents for its all-dry, zero-waste cathode synthesis process in the United States (US12378132), Europe (EP4021854), and Japan (JP7504195B2), with additional applications pending. This patented process delivers NMC cathode synthesis technology for materials that are drop-in ready with conventional nickel-based cathode powders.

Single crystal NMC, such as NMC 631, NMC 811, and NMC 9055 have each been demonstrated, and these materials have been successfully sampled to a variety of external parties. But the process technology goes beyond these materials in a continuum of chemical compositions.

Reach out to our team to learn more about our patented all-dry, zero-waste technology and how it can help decrease cathode production costs and improve its environmental footprint.

Free On-Demand Webinar

All-Dry, Zero-Waste Cathode Synthesis: Technology-Enabling Solutions to Sustainable, Low Cost Materials Production

Watch the on-demand webinar with Dr. Mark McArthur, Director of Cathode Technology for NOVONIX, as he explores how our patented all-dry, zero-waste synthesis method is revolutionizing lithium-ion battery cathodes. Learn how this innovative process produces high-performance, single-crystal NMC powders without using liquids, optimizing both battery cost and sustainability.

To access the webinar, please fill out the form below.

"*" indicates required fields

Strategic Partners

To download the whitepaper, complete the form below.

"*" indicates required fields

Discover All-Dry, Zero-Waste Cathode Synthesis

Our patented all-dry, zero-waste cathode synthesis technology (JP7504195, US12378132, EP4021854) is the first of its kind, eliminating the need for precursor materials and directly converting raw metal feeds into finished NMC cathode active materials.

- A patented breakthrough. A word-first, fully scalable method for producing precursor-free NMC cathode powders.

- A sustainability game-changer. No water. No complex reagents. No sodium sulphate or ammonia byproducts. A dramatically smaller manufacturing footprint.

- A cleaner supply chain. Reduced land use, lower power consumption, and a more efficient, cost-effective process.

- Broad chemistry compatibility. Designed for NMC compositions ranging from 50% to 95%+ nickel.

Working Together

With the cathode materials market projected to exceed $100 billion by 2030, and processing accounting for 10% of that, NOVONIX is well-positioned to make an impact. As the industry pushes for lower costs and greener solutions, our innovative cathode synthesis process offers a competitive edge.

We continue to build strategic partnerships while exploring licensing and joint venture opportunities.

Interested in partnering with us or learning more?